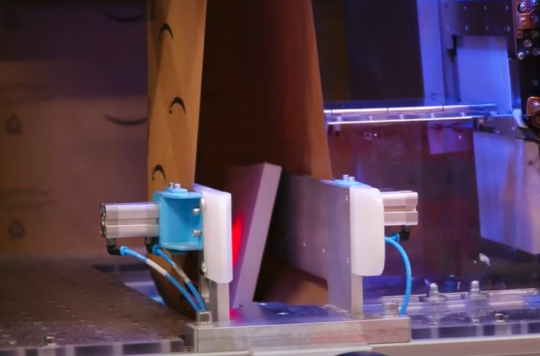

Upcycling is in the spotlight at Amazon. The e-commerce giant has just brought out its bagging machines, which have been in the closet since the end of single-use plastic delivery bags in Europe.

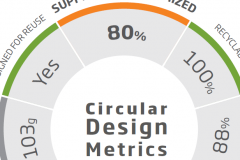

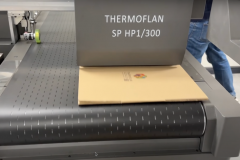

These machines have been converted to handle thin coated paper instead of plastic, and to overwrap each item individually and to size. The operator places the product to be shipped in the machine, an integrated sensor scans it and calculates the volume of packaging required, then the paper is cut and sealed around the product, leaving no empty space. More cushioning material, the use of lightweight paper, tailor-made packaging - all this would mean twenty-six grams less on the scales for each shipment, according to Amazon.

"Our materials science experts have developed a paper that is both lightweight and strong, which stretches, is more weather-resistant and lends itself to heat-sealing like plastic, while being easily recyclable in the selective sorting process." says Thais Blumer, European Sustainable Packaging Manager at Amazon.

The new process is currently being tested at two distribution centers, in Mönchengladbach, Germany, and Bristol, UK.

"Our tests confirm that this technology is efficient, safe and reliable and can therefore be deployed on a large scale." says Thais Blumer.

Amazon hopes to develop this technology in order to package not one, but several products together using a more robust paper or cardboard.

By using paper bags, cardboard boxes and cardboard envelopes for its traditional shipments in Europe since 2015, and replacing bubble wrap with paper, Amazon claims to have reduced the average weight of its packaging by 41%, which would represent over 2 million tons of packaging materials saved.