Glassine

Last layer of the label. See " Backing ".

Width

The width is the width of the roll or label.

Mandrel

Cardboard or plastic tube on which the labels are wound.

Metamerism

Difference of perception of a color according to its lighting.

Cutting tool

Engraved steel die or magnetic plate cutting the forehead at mid-chair or full-chair depending on the setting

PE (Polyethylene)

A type of synthetic, flexible surface used in the food industry for the production of bottle labels. PE is resistant to moisture, but shrinks when heated.

PEEL

FINAT standard. Traction force required to peel the label from the substrate at a defined angle and speed.

Pregosity

Ability to adhere a label without applying pressure.

PET (Polyester)

Synthetic surface of the protector, rigid, resistant to moisture and heat. PET is particularly suitable for durable labels.

PP (Polypropylene)

Synthetic surface of the protector, flexible and resistant to moisture. PP does not tolerate heat well and deforms when stretched.

Protector

See " Backing ".

Release

Force exerted to lift the forehead from the protector.

RFID (RFID tag)

Electronic label allowing to receive and transmit information at a distance. They correspond to a technological process of identification by radio frequencies.

Winding direction

Depending on the customer's industrial needs, the labels can be wound on the inside or outside of the reel.

Exit direction

Orientation of the label on the reel, determined according to the configuration of the automatic application during the packaging step.

Silicone

Non-stick protector covering the backing. The more silicone there is, the easier it is to remove the label.

Substrate

Element intended to receive the label (bottle, flask, packaging, etc.).

Support

The backing of a label is the face, which is the first layer of the labelstock. It is this side that is printed.

Tack

In the ink industry, tack is also known as "stickiness" or "pulling". It is the resistance of the ink film to splitting into two parts. It characterizes the transferability of the ink. Some resins have the advantage of increasing the viscosity of the ink without increasing the tack.

The tack of a label is also referred to as the force used to separate it from its substrate after a very short application time and without applying pressure.

Heat transfer

Printing mode used in particular for variable data in the fields of logistics and industry. It is based on a system working with an ink ribbon heated by the print head. The ink is deposited on the support under the action of heat in a durable and reliable way.

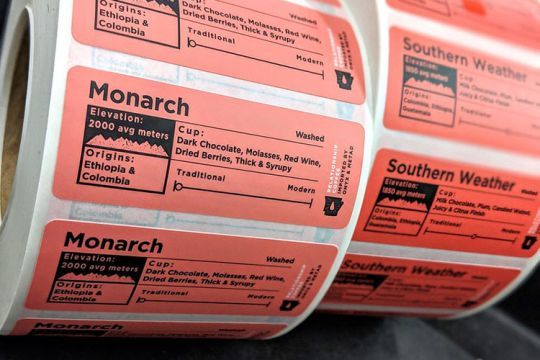

Image source: Sticker Giant