DS Smith, which operates plants in more than 30 countries, employs 30,000 people who need to be continuously trained on various machines and technical processes. After a long search for an interactive training solution, the paperboard packaging solutions manufacturer opted for virtual reality.

Virtual reality is "an excellent way to reproduce training on the workstation, without logistical constraints, without any risk, without stopping the production line and without monopolizing the managers" he explains.

The plant located in Nantes, DS Smith Packaging Atlantique, was the pilot site for these training sessions. And the results are conclusive. These training courses would offer "improved efficiency in learning and reduced training time", "increased safety and quality awareness".

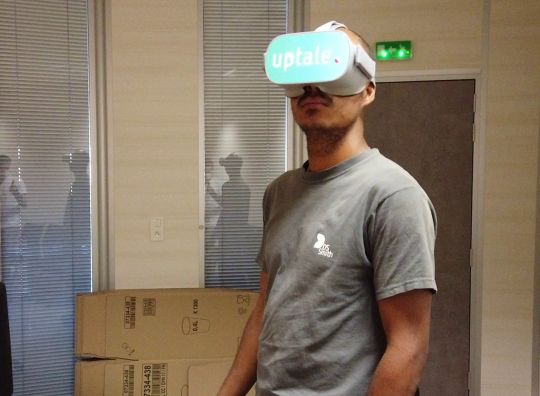

The training requires a virtual reality helmet. The person equipped with a virtual reality helmet moves through 360° images and videos of the industrial environment. Instructions indicate the actions to perform and the points of vigilance. This training has been designed with a video game spirit.

These trainings can be deployed remotely, without virtual reality headsets, on smartphones and computers. "Just walk around the scenery and click on the different 'points for action', just like you can do on Google Maps' Street or Pokemon Game." says DS Smith.

Today, a large number of sites in France and Europe are already using this platform. A dozen immersive modules have already been produced in several languages, such as the one dedicated to the process of changing coils on a corrugator that can be seen on YouTube.