In the south of Brussels, the former premises of an American electronics manufacturer have been transformed into a production line dedicated to a new kind of organic material: mycelium. Since the beginning of October, the young Permafungi company has been based here, industrializing a compostable, biosourced and local packaging process based on mushrooms.

A mushroom-based process to replace expanded polystyrene

Born in 2013, Permafungi first experimented with growing oyster mushrooms from urban coffee grounds. This pioneering activity, already focused on the logic of waste reuse, gradually gave rise to applications in the materials field. Mycelium, the vegetative organ of mushrooms, is now the raw material for a new type of packaging, presented as an alternative to expanded polystyrene.

After two years of work, the new site totals 1400 m 2 including 1000 m 2 will be devoted to growing and shaping the material. The facility incorporates photovoltaic panels and a rainwater recovery system. According to Julien Jacquet, co-founder and CEO of Permafungi, the plant required an investment of 2.5 million euros, partly financed by a grant from the European Life program.

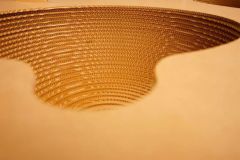

In this plant, local sawdust mixed with mycelium and water produces, after a few days' growth in molds, this new material that is both solid and light, with technical properties close to those of expanded polystyrene (EPS) but which can be degraded into compost. This material is generally smooth and white, says Permafungi on its website.

Permafungi currently targets high-end hotels and soap factories, like its customer Savonneries Bruxelloises. The brand-new site is expected to produce 100 m 3 of packaging per month.

"No reason to trust plastic anymore"

This plant, which claims to be the "Europe's largest producer of biobased and biodegradable packaging" "create elegant, tailor-made packaging that nourishes the soil instead of polluting it"

And Gilles Grosjean Nash, who is in charge of business development, adds in a press release: "I'm a firm believer in the power of mycomaterials in the packaging sector. Mycomaterials are innovative, but concrete. Ultralight and 100% biodegradable."

He points out that this type of natural material requires ten times less CO2 and eight times less energy than polystyrene foam production, while offering a competitive price. "Fire- and water-resistant, circular and aesthetically pleasing, they can also be customized (by laser engraving, editor's note). In short, our customers and future customers no longer have any reason to rely on plastic." he sums up.