In response to the growing demands of print professionals, Roland DG is offering three new pieces of equipment tailored to the specific needs of the textile, signage and packaging prototyping industries. From DTF technology to eco-solvent printing, as well as a solution dedicated to the production of packaging prototypes, these new products aim to diversify print shop capabilities.

Optimized DTF printing with the Roland DG TY-300

The TY-300 Direct-to-Film printer is aimed primarily at professional textile printers, such as branding studios, personalized garment designers and manufacturers of various textile products.

This machine combines high image quality with increased productivity thanks to newly developed printheads and parameters True Rich Color 3 . Two white ink density profiles enable prints to be adapted to different types of textiles, from light to dark fabrics. What's more, the TY-300 comes with a dedicated powder shaker, guaranteeing even application of hot-melt powder and efficient curing.

The S-PG2 ink system reduces ink consumption and waste, responding to the ecological concerns of companies. Certified OEKO-TEX ECO PASSPORT, the inks and powders used comply with rigorous safety standards for human health and the environment.

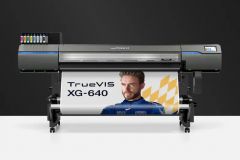

TrueVIS XP-640: an eco-solvent solution for high-quality signage

With the TrueVIS XP-640, Roland DG expands its range of large-format printers, targeting the signage and graphic arts sectors. Designed to meet high production volumes, this 64-inch printer offers a combination of quality and speed, thanks to its double-row printheads and advanced data control technology.

The new TH eco-solvent inks, including additional hues such as red and orange, enable faithful reproduction of brand colors and a significant extension of the colorimetric gamut. In addition to reducing costs per milliliter, these inks offer improved consumption management thanks to optimized print profiles.

On the practical side, the XP-640 features a 7" touch panel, automatic media adjustment and a precise winding system. What's more, users can replace wear parts themselves, minimizing production downtime.