Packaging manufacturers knew it: autoclave sterilization was one of the last obstacles to the recyclability of flexible packaging. This constraint, linked to the high temperatures of the process after filling and sealing, has until now imposed complex multi-layer structures that are impossible to recycle. Bobst, Brückner Maschinenbau and Mitsui Chemicals announce that they have taken a significant technical step forward by developing a single-material structure, resistant to the retort sterilization process and compatible with existing recycling channels.

This development, a world first, was unveiled at K 2025, the international plastics and rubber trade fair held in Germany in October. It is a high-barrier metallized polypropylene film, incorporating ultra-thin layers of heat-resistant coatings. Bobst mobilized its expertise in vacuum metallization, Brückner supplied the extrusion and orientation technology with in-line coating, and Mitsui developed a heat-resistant primer.

The challenge: barrier coating resistance to sterilization

The critical point was the film's ability to retain its barrier properties after autoclaving. According to Anrika Heermant of Mitsui Chemicals Europe, the challenge was more specifically to ensure that the coatings remained in place, and to protect the metallized layer from corrosion in the presence of steam. At the same time, the dimensional stability of polypropylene during thermal cross-linking posed challenges in terms of substrate shrinkage, which could alter barrier integrity.

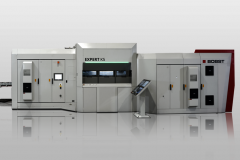

To meet these requirements, Brückner designed an in-line coating process that enables the application of very thin but sufficiently resistant layers. The resulting films were metallized with AluBond technology on Bobst Expert K5 equipment at Bobst's Manchester Competence Center.

This treatment, already tried and tested in other barrier applications, improves interlayer adhesion, stabilizes surface energy and guarantees Oxygen Transmission Rate (OTR) and Water Vapour Transmission Rate (WVTR) performances judged to be the best in the industry "excellent" after sterilization.

Mitsui completed the structure with a top coating and a bonding resin. The result is a single-material solution that works, although it is not yet available for industrial production.

Animal feed outlets

The solution is aimed primarily at food applications requiring thermal sterilization in an autoclave, in particular animal feed, a segment that consumes a lot of complex aluminum-PE or PET-PP structures. As these types of packaging are covered by new European regulations, notably the future Packaging and Packaging Waste Regulation (PPWR), the availability of solutions compatible with single-material recycling channels is becoming a strategic issue.

The three partners are now planning to open up the project to other manufacturers to validate its large-scale reproducibility.