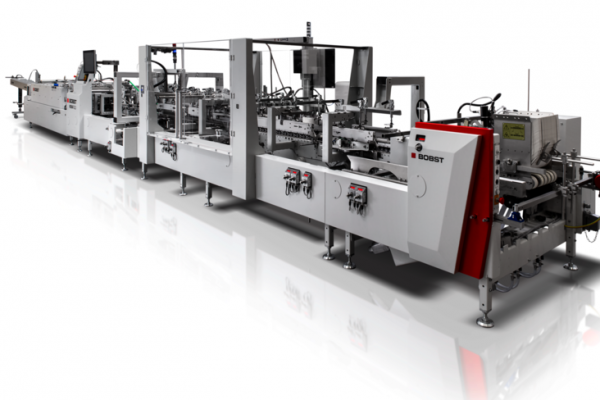

Launched to meet the daily needs of folding carton manufacturers, Bobst's Novafold folder-gluer benefits from a significant technical update. The Swiss manufacturer has made several productivity-enhancing modifications to models 50, 80 and 110.

According to Pierre Binggeli, product line manager for folder-gluers at Bobst, the priorities focused on "increased speed, improved bending quality and simplified set-up and changeover times for operators" .

From 18‚euros000 to 22‚euros000¬ cans per hour and controlled folding on long formats

And indeed, one of the most remarkable developments is the increase in speed. Conveyor speeds have been increased from 300 to 350 meters per minute, while folding capacity has been increased from 18‚euros000¬ cans per hour to 22‚euros000¬ cans per hour.

In addition, the effective length of the bending section has been increased from 2‚euros300 to 3‚euros000¬ mm. This extension slows down the bending process, with better control of the output. This change is of particular benefit to users handling extended formats or more fragile materials, minimizing stress on the substrate and limiting rejects.

In addition, the Combifolder side doors have also benefited from improvements that should optimize accessibility to the internal modules, particularly for adjustments and maintenance operations. A pneumatic locking system has also been integrated into the infeed ramp, reducing lateral set-up times.

Simplified production settings

The upgrade includes the optional Sphere interface, already available on other Bobst equipment. This digital environment enables work parameters to be recorded and recalled, via digital positioning indicators. The aim is to standardize settings from one operator to another, limit machine downtime and facilitate the preparation of repetitive jobs.

Direct transmission of settings from a back-office station enables production planning. Operators have access to an ordered list of upcoming jobs, with saved configurations, avoiding the need for manual re-entry.

The Novafold retains the Accueject system, a module for automatic ejection of non-conforming boxes, activated without interrupting the flow.