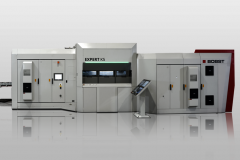

As corrugated converters are not all looking for the same machine widths or line configurations, Bobst is upgrading its folder-gluers, with a range more tailored to formats and applications. Two new versions, the Expertfold 106 and Expertfold 215, now complete the range previously comprising the Expertfold 145 and Expertfold 165.

Expertfold 106, a reduced footprint

Designed for small microflute cans, the Expertfold 106 has the smallest width in the range, at 1060 mm. Bobst emphasizes the machine's limited footprint (18 m x 2.43 m), often a decisive factor in workshops with limited floor space. This version incorporates the platform's technologies, with particular attention paid to the preservation of laminated packaging surfaces, which are sensitive to marks and scratches.

Expertfold¬ 215 for carton parts up to 2‚euros300¬ mm

At the other end, mainly intended for large formats for e-commerce the Expertfold¬ 215 can fold and glue blanks up to 2‚euros300¬ mm wide. This folder-gluer features an extended infeed section, as well as folding (6‚euros000¬ mm) and outfeed (6‚euros600¬ mm) sections. To reduce machine length, the pre-cutting module can be removed.

Like the Expertfold 145/165, the Expertfold 215 can be equipped with Polyvacuum and Gyrobox XL systems, for in-line application of adhesive tapes and opening strips, enabling the production of complex boxes in a single operation.

A few months ago, Bobst updated the two previous Expertfold 145/165 models, which now feature an automated sheet aligner, new job management capabilities and fully digital recipes.