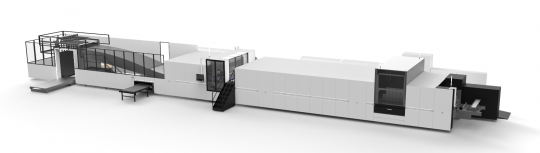

Unveiled at Drupa 2024 as a prototype, the Canon corrPress iB17 is now available. Officially launched at the 2025 technical seminar of the European Federation of Corrugated Board Manufacturers (FEFCO), this press marks the Japanese manufacturer's entry into the industrial digital printing market for corrugated board.

Developed to meet the demand for shorter runs, more variants, faster turnaround times and top-of-the-range quality, this large-format inkjet press promises output of up to 8‚euros000¬ m 2 /h.

80% of retail packaging applications covered with corrPress iB17

The corrPress iB17 processes corrugated board sheets up to 1.7 meters wide and 1 and 8 mm thick, with an annual capacity of up to 15 million square meters. This capacity covers around 80% of retail packaging applications, says Canon.

According to the Japanese manufacturer, its productivity would make it possible to envisage economically viable production runs of up to 20‚euros000¬ m 2 per order, beyond the traditional field of short runs.

Near-offset quality for corrugated printing

The corrPress iB17 is equipped with 1200 DPI piezoelectric printheads designed by Canon. The machine uses water-based pigment inks specially formulated for corrugated, plus a primer. The whole system is compatible with indirect food contact.

At present, it prints in CMYK, but in the future it will be possible to add orange, violet and green (OVG) inks.

Canon has chosen to apply the ink immediately after the primer, with no intermediate drying phase, thus limiting deformation of the substrate. The press is also equipped with an optimized drying module to reduce stress on the material, as well as energy consumption.

The corrPress iB17 also incorporates an automatic head cleaning and quality control system, designed to reduce human intervention.

Canon also specifies that the quality obtained, close to offset, makes it possible to dispense with lamination on coated or uncoated substrates, at nominal speed, with a final rendering claimed to be sufficiently stable, precise and colorful for demanding applications.

The Japanese manufacturer points out that it has in-house expertise in the three key components of the ‚euros system: heads, inks and ‚euros drying technology, which facilitates adjustments and process stability.