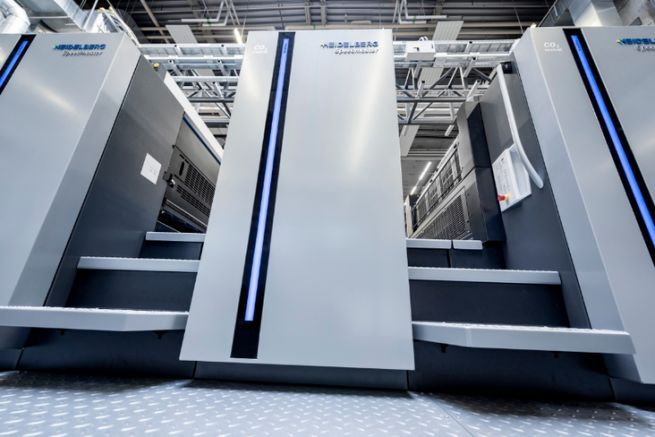

At the first international event since the covid outbreak - the China Print show held June 23-27 in Beijing - Heidelberg unveiled the Speedmaster CX 104. The 15,000- or 16,500-sheet-per-hour sheetfed offset press replaces the CX 102 and CD 102, which, with more than 125,000 units installed, are Heidelberg's best-selling presses worldwide-perhaps all manufacturers combined.

The CX 104, the sheetfed offset press for commercial, packaging and label applications

"Designed for ease of use, the CX 104 press is a highly versatile sheetfed offset press for both the industrial commercial and packaging/label sectors, presents Hubert Viger, sales support and Sheetfed expert at Heidelberg. Thanks to its paper passage quality and increased format, the CX 104, which is based on the XL 106 press, has a media range from 0.03 to 1 mm thick, perfectly suited to thin as well as thicker media: it is 'all terrain'!"

A completely redesigned paint group

Another highlight is the coating unit. Heidelberg has created a coating unit with simplified operation, faster makeready and further improvement of the coating quality.

It supports both metal-web coating blankets, flexible polymer coating plates (Folacoat) and aluminum-based plates. It is also compatible with the CX/CD 102 coating forms.

The pressure on the anilox can now be adjusted from the press console, as on the XL 106.

And the coating unit is now at the same level as the printing units. "This allows for the integration of an anilox storage area to have different types of anilox available to vary the rendering of the coating" emphasizes Hubert Viger.

An offset press with improved ergonomics

The new design of the coating unit also allows a single operator to change the anilox in 1 min 23 s compared to about 6 minutes with two people on other versions of the press. "That's quite a performance!"

The entire Speedmaster CX 104 has a new design. For example, the corners have been rounded for a softer shape and the steps are lower. "Overall, the design has been modified to increase operator comfort."

"The CX 104 can also integrate an ink misting extraction system, which in the UV world is known as a 'voltige'. This recovery system allows to contain the misting of UV and led UV inks and to prevent it from spreading in the production workshop. The cleaning of this air takes place directly in the printing units."

Extensive automation based on the XL 106

There are many automation features on this press, many of which come from the XL.

The CX 104 is equipped with the Autoprotect solution (optional): " This automatic system protects the unused units during production, thanks to the lubrication of the inking unit, which is entirely managed by the Intellistart 3. The surface of the rollers is thus protected. For the next job, the machine will automatically implement the washing of the rollers of the units that have been protected."

The calibration processes are also determined automatically in order to guarantee short times.

An offset press for which types of printing companies?

In the labor sector The CX 104 is designed for printers who work in one or two shifts and who need to print 25 to 30 million sheets per year, according to Hubert Viger.

And in the packaging and label sector The CX 104 is particularly suitable for small and medium-sized printers (with sales of between EUR 6 and 8 million), according to Olav Spielmann, Packaging Sales Support at Heidelberg. "These companies have different needs than large corporations. They don't need to reach 18,000 sheets/hour (like with the XL 106). Speed isn't quite the name of the game, but they do require an ergonomic, easy-to-use offset press with an appropriate financial cost."

"And of course, being versatile, the CX 104 press will meet the hardworking people who want to diversify into packaging . Covid has had the effect of creating demands for local packaging. And this machine fits those new demands."

Heidelberg, which opened orders three months ago, has already recorded sales of 500 units worldwide. And in June, a packaging printer installed the first CX 104 in France.