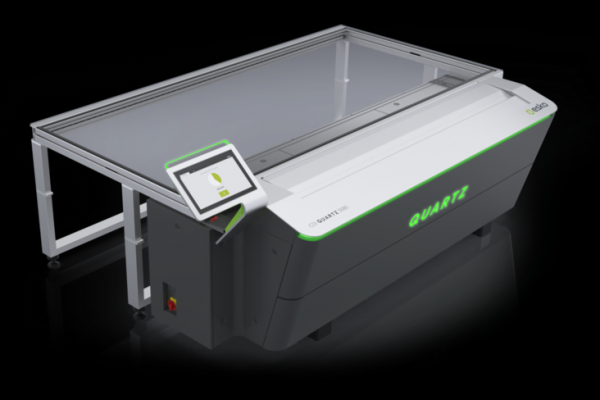

Previewed at Drupa, Esko's Quartz flexographic system is now available to order worldwide, in three formats: 4835, 4260 and 5080. Quartz, which complements the existing Crystal range, is positioned as a high-end, integrated flexographic photogravure solution.

The Belgian manufacturer promises a significant advance in print quality, consistency and uniformity. "In the field of flexible packaging, rotogravure is still widely regarded as offering the best print quality says Jan De Roeck, Esko Marketing Director. Thanks to the Esko Quartz ecosystem, we offer printers the opportunity to achieve this print quality in flexography."

Double the resolution of other systems

The heart of this new technology, comprising the Quartz CDI imaging system, the XPS exposure unit and Quartz screening technology, lies in a dual optical system and a resolution increased to 4000 ppi, almost double that of current standards.

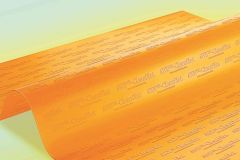

Combined with an engraved screen at 2000 lpi (Quartz Cells), the process offers a significant improvement in ink transfer. According to Pascal Thomas, Director of Flexo Product Management at Esko, this improvement in quality means that converters can approach the quality of gravure engraving, thanks in particular to better solid coverage and deeper shadows.

The technology is also based on an evolution of the in-house Print Control Wizard software. This takes into account a range of parameters âeuros from plate type to ink behavior and UV exposure settings âeuros to automate Crystal screen generation. Quartz introduces two new types of screen: VQ Cells (variable screens for high light conditions) and SQ Cells (stochastic screens), for even greater rendering precision.

The system is designed to work optimally with XPS Crystal UV LED exposure units, ensuring exposure homogeneity across the entire plate surface. According to the manufacturer, this technological combination guarantees reproducible, clean and long-lasting results.

Compatible with both water-based and solvent inks, the Esko Quartz ecosystem is presented as a production tool facilitating the transition to more sustainable practices. For water-based inks, Esko claims a density gain of up to 0.7. According to Esko, this performance will enable smooth, artifact-free solids to be obtained, while reducing the quantities of ink required.

Initial positive feedback from Inci-Flex

Among the first users, Italian prepress house Inci-Flex, which specializes in flexographic and rotogravure printing for flexible packaging, reports results close to those of gravure engraving.

Managing Director Vincenzo Consalvo tells Esko: "As one of the world's first adopters of this technology, we've seen a quality improvement comparable to gravure, offering more uniform ink coverage, better contrast and deeper shadows."

He adds, "Esko CDI Quartz also eliminates dot bridges and achieves new levels of solid ink density, making our prints cleaner and brighter." For him, the Esko CDI Quartz has "high standards of plate-making quality" from Inci-Flex to "a higher level".