At the Gallus stand in Barcelona, Asahi Photoproducts will be presenting the extension of its AWP Ecosystem, a modular unit for the production of flexographic printing plates in a solvent-free environment. Developed by Asahi Kasei, a Japanese chemical group also active in filtration membranes, AWP Ecosystem is aimed at short-run label printers with constraints in terms of energy consumption, liquid waste and makeready time.

AWP Ecosystem, a system that reuses 90% of water

The system comprises a new generation of AWP photopolymer plates, a processing unit and a closed-loop water recycling system.

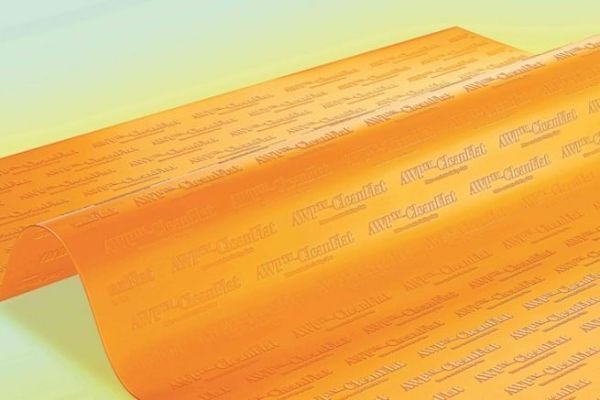

The AWP flexo plate is "water-washable", i.e. washable only with water, without the addition of solvents or detergents. Asahi describes it as offering high-definition print quality, consistent performance and reduced machine downtime.

The processing unit, named AWP-2530AA, is specifically designed for small-format flexo plates.

And the third element of the system is the compact AWP-Loop Petite recycling station.

It is based on Microza technology, already used in industrial filtration applications at Asahi Kasei, and can reuse up to 90% of the water in the treatment cycle.

The first complete line using only water, with no additives or detergents, is currently in operation at The Oldham Group, a U.S.-based processor.

The new system is scheduled to go on sale "in the near future", according to the Japanese manufacturer.

A larger AWP-LOOP and a new plate under development

Asahi also announces that a large-format version of the AWP-Loop unit is currently under development.

At Labelexpo 2025, Asahi will also be presenting samples printed with a new FlatTop plate, which is also in the development phase. The FlatTop plate "is designed for high ink densities and fine, sharp, detailed print" . No details were given.