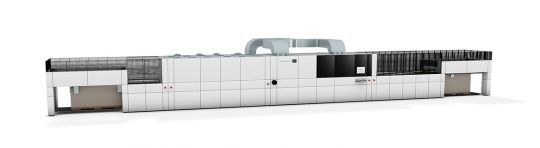

At its open house at the Durst Innovation Center East in Austria on May 12, digital packaging printing systems joint venture Koenig & Bauer Durst unveiled its new digital corrugated press, the Delta SPC 130 FlexLine Eco+.

Less automated than its big sister the Delta SPC FlexLine Automatic the Delta SPC 130 FlexLine Eco+ is a compact entry-level model for converters with volumes of 4 to 8 million square meters per year. This new press can be upgraded to the FlexLine Automatic at a later date.

"It's clear from the discussions we had at our SPC open house that processors increasingly need the capabilities and skills to mass customize without any compromise on quality, all at an efficient cost of ownership. That's what we offer them." says Robert Stabler, Managing Director of Koenig & Bauer Durst.

Like the Automatic, the Delta SPC 130 FlexLine Eco+ uses water-based, food-safe inks and handles media up to 1.3 meters by 2.8 meters.

DNM, a new dynamic nozzle management tool, reduces maintenance

The new press is equipped with the latest Dynamic Nozzle Management (DNM) technology. This tool significantly reduces printhead maintenance.

"The tool locates nozzle clogging and can then be programmed to manage the level of ink thrown from the head. It ensures that high quality production is maintained." explains Koenig & Bauer Durst.

The DNM will equip the entire Delta SPC 130 range and can be retrofitted to existing machines.