Maintenance of the print heads

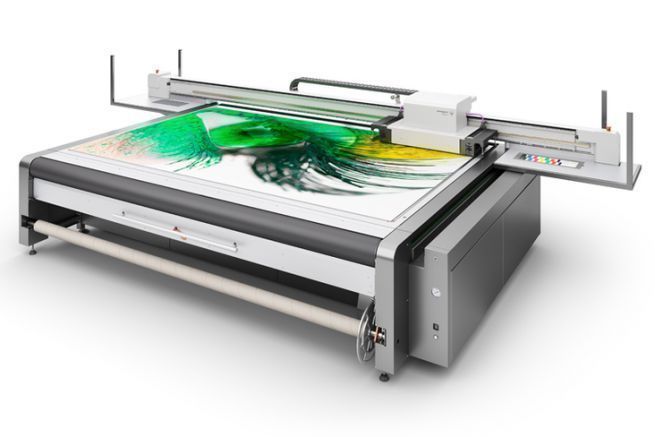

Depending on the media used, more or less maintenance work is required. The automatic cleaning of Mimaki print tables has three levels of "cleaning" (like most manufacturers): soft, normal and hard. In the case of repeated printing on media that tend to reflect UV light and scour the ink at the print nozzles, such as glass, for example, the automatic maintenance can be reinforced by manual cleaning of the heads.

The manufacturer Swiss Q Print recommends cleaning the print heads in the morning and evening and reminds that the visual control is very important . Only the human eye can detect any particles of the print media that may have been thrown onto the heads as the carriage passes.

To work serenely, the daily maintenance of the print heads is to be privileged, that it is entirely automated, as it is the case with the HP Latex machines, or that it is associated with a manual cleaning. The type of ink can also have an impact on the frequency of maintenance cycles.

Cleaning a flat table top

A common mistake made by many printers is to omit the cleaning of the printing plate. However, a clean plate is a guarantee of quality printing over time. On a daily basis, a soft cloth soaked in alcohol is enough. A wooden or plastic scraper helps to remove the hardened ink without forming scratches. And regularly, do not forget to dust the rail.

When printing on thick media, 5 cm for example, it is advisable to place shims of the same height around the media in order to flatten the table. This avoids the formation of an ink mist drying the heads. The goal is to print on as flat a surface as possible.

The production area also deserves special attention. The environment must be kept clean at all times. For this reason, a panel cutting machine should not be placed near the printing area.

Damaged nozzleeuros head to change

A clogged nozzle instantly causes a loss in print quality. For many reasons, inkjet printers sometimes underestimate printhead cleaning. However, not devoting 10 to 30 minutes of daily cleaning is to take the risk of having to replace the heads early: such negligence can cost between 1,000 and 6,000 euros, according to a representative of the Liyu brand.

Even if the machine is not used much, it still needs to be cleaned regularly to prevent the ink from drying. The automatic vacuum is not sufficient for proper maintenance.

In case of deflection, when the drop goes off at an angle creating a "banding" effect instead of falling straight onto the media, the operator must quickly intervene. Wetting the printheads with cleaning fluid will soften the ink blocking the nozzle. The passage of an adapted rag and sticks (one by head not to mix the colors) evacuates the deposits. A good automatic cleaning cycle completes the cleaning operation.

Overall, the maintenance of a flatbed depends on the manufacturer's recommendations, as there are many different automation technologies, each with its own specificities. The frequency of cleaning (heads and printing plate) is determined by the rate of use: it varies from daily to weekly. The least you can do is to perform a thorough cleaning once a week to ensure that you get the most out of your investment.