In the run-up to Drupa 2024, Highcon unveils its new products for the cardboard packaging sector, which will be presented at the major graphic arts trade show. Three of them are now available.

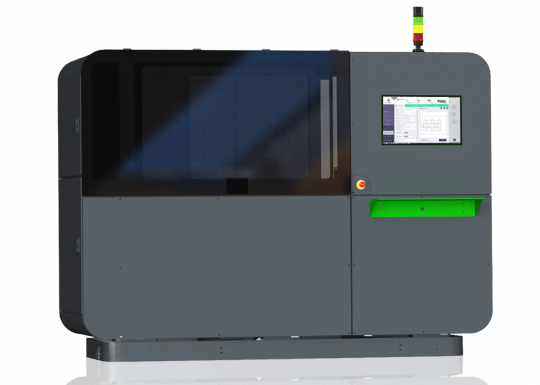

Highcon Beam 3, the digital diecutting and creasing solution for folding carton and microfluting

The digital die-cutting and creasing solution for folding carton and microflute, Highcon Beam 3, will deliver around 25% more output than the Beam 2 solution, with higher, more consistent quality. Combined with the new optional Beam Writer offline module, Highcon Beam 3 offers a 50% increase in productivity over the current solution.

With this machine, a converter will be able to handle 10 runs averaging 1,000 sheets per shift. Return on investment for customers is typically less than two years for a two-shift operation, according to Highcon.

An existing Beam 2 system can be upgraded to this higher version with the Productivity & Quality Boost kit.

Beam Writer, the offline digital creasing system

As for the new Beam Writer module, compatible with all existing Highcon Beam systems, it enables the off-line creation of creasing fillets using Highcon's DART (Digital Adhesive Rule Technology) system. The DART system uses the digital data from the creasing files to reproduce them via the special DART cartridge, which releases a polymer onto a Highcon DART sheet. Once hardened, the lines created with this polymer will form the shape to be scored.

Over 100 prints per month, this module would free up more than 16 hours of Beam system capacity.

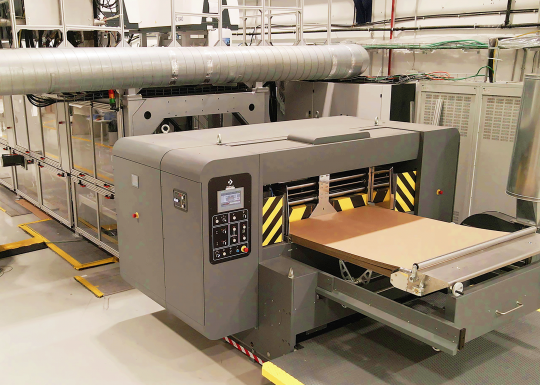

The improved Highcon Beam 2C cutting and creasing solution for corrugated board

Highcon has also worked on the Highcon Beam 2C digital diecutting and creasing solution for the short- and medium-run corrugated market, to improve its performance. This improved version offers a 15% increase in operating speed for manufacturers of corrugated packaging, POP and displays.

Combined with the Beam Writer, the Beam 2C boosts productivity by up to 50% compared with the previous model.

Highcon's Vulcan, a promising corrugated die-cutting machine under development

The Highcon Vulcan diecutter is a new-generation system with a format of 1.4 x 1.7 m (55 x 66 inches) that handles corrugated board up to 5 mm thick, including microflute and B-, C- and EB-flute board for packaging and display applications.

Like all Highcon systems, this machine, still under development, will combine physical creasing and laser cutting, with a maximum output of 3,000 large-format sheets per hour (i.e. up to 7,000 m 2 /h). Changeover time takes 5 to 10 minutes.

When development of the Vulcan system began in 2022, four customers (Germany's Thimm Group, the USA's The BoxMaker, Poland's UDS and Mexico's Grupak) showed their interest in the future machine by paying a deposit. In 2023, German manufacturer Schumacher Packaging joined them, signing a memorandum of understanding to purchase 5 to 10 Vulcan units from Highcon before 2030.

Bjoern Schumacher, CEO of Schumacher Packaging, is delighted with the Highcon Beam 2 C solution. He comments: "You have to see it to believe it: the demonstration of the prototype I saw in Israel last June convinced me that the Vulcan was really going to be a game-changer for us."

The first Vulcan unit is scheduled to be installed at a customer site for alpha testing in 2026. At Drupa, visitors will be able to see samples made with the Vulcan prototype.