The packaging and rotogravure industries have always placed color accuracy at the heart of their concerns. The Pantone certification obtained by BOBST for its oneECG technology marks a turning point in rotogravure printing.

BOBST's Pantone certification for oneECG gravure technology ensures color consistency, a key point for brand owners. The ability to faithfully reproduce more than 2,300 Pantone spot colors with a level of precision unheard of in gravure opens up new perspectives in this process.

Indeed, rotogravure, often chosen for its long-run capabilities, has always faced challenges in terms of color stability. The use of the ECG process, based on a set of standardized inks (often seven), now overcomes these limitations, guaranteeing reliable chromatic results, whatever the print run.

Color variations have long been a major concern in the packaging industry. Studies show that 42% of brands consider color problems to have a negative impact on their business, resulting in costly rework and additional delays. ECG technology is essential here, as it eliminates variations due to human interpretation and variable production conditions.

With oneECG, BOBST has worked on digitizing the color matching process, making production more stable and consistent. Pantone certification confirms that this technology meets the most stringent color reproduction standards.

BOBST's oneECG technology offers numerous operational advantages. First and foremost, it reduces press downtime, a key factor in optimizing production costs. With a fixed set of inks, printers no longer need to change cylinders for each new job, considerably reducing material and time wastage.

What's more, this technology offers greater flexibility for short and medium runs, an area where gravure has historically been less competitive with other printing processes. Now, medium-sized runs of around 5,000 m² can be produced with improved profitability, opening up new business prospects.

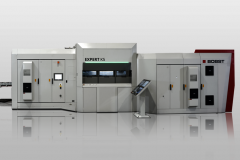

The BOBST MASTER RS 6003 gravure printing platform has been awarded Pantone certification. This machine stands out for its flexibility and multifunctional capabilities, enabling it to meet a wide range of applications in flexible packaging, corrugated board and folding carton. Thanks to oneECG, the MASTER RS 6003 ensures color consistency on all types of substrate, while guaranteeing rapid production.