Are you making a strategic investment, modernizing your equipment or adopting a new technology? Share your initiatives with us, and let the printing and graphic arts community know about your projects. Every week, we highlight the investments that are shaping the future of our industry. Send us your press releases and information, and take advantage of this showcase to highlight your strategic choices and inspire other professionals â?" and weâ??ll keep you informed Click here .

Two strategic investments boost production capacity at SIEL (43)

In September 2024, SIEL integrated a new MECANUMERIC machining center into its workshop, optimizing the machining of materials such as PMMA, PVC and polycarbonate. This equipment enables custom lettering and shapes to be produced with greater precision, while improving production times. The swissQprint NYALA 4 will shortly be joining the SIEL workshops, marking a technological breakthrough in UV flat and relief printing. This acquisition pushes back the limits of personalization and creativity, while offering new solutions tailored to customer needs.

Foxprint (62) adds Summa F1612 cutting table to its fleet

Foxprint, a company specializing in digital printing and installation of communication media, announces the integration of a new Summa F1612 cutting table. This versatile equipment, equipped with tangential modules, opens up new perspectives for cutting and milling a wide variety of materials. Founded after ten years' experience in the sector, Foxprint continues to invest in cutting-edge technologies to offer ever more comprehensive and eco-responsible services, from production to installation.

ABSR (47) invests in AGFA's Jeti Tauro H3300

Based in Villeneuve-sur-Lot, between Toulouse and Bordeaux, ABSR is equipped with the Jeti Tauro H3300. Capable of producing up to 905 m²/h, it offers a maximum width of 3.3 meters and supports extensive color configurations (CMYK, white, varnish). Its configurable automation system enables long production runs to be handled with great stability. Versatile, it prints on both rigid and flexible substrates, guaranteeing uniform solids and precise gray balance.

Les Impressions Réunies (45) installs the Asensia MP Series for large-format printing

Les Impressions Réunies, based in Ingré in the Centre-Val de Loire region of France, is expanding its production capacity with the arrival of the Asensia MP Series printer. Designed for large-format printing, this machine boasts a printable area of up to 3200 × 2000 mm, a production rate of 90 m²/h, and can handle rigid substrates up to 100 mm thick. Equipped with Ricoh Gen 6 printheads, it guarantees precise image quality and limited downtime. Its UV LED curing system and nano-pigment inks enhance adhesion and durability on a wide variety of materials, such as wood, metal or Plexiglas. Incorporating advanced features such as positioning cleats and anti-static bars, the Asensia MP Series optimizes production workflows and reduces waste.

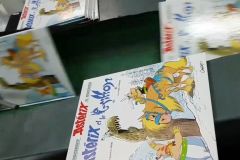

Imprimerie Pollina (85) optimizes production with new Kodak Magnus Q3600 Titan CTP system

Imprimerie Pollina, based in Luçon in the Pays de la Loire region of France, continues to strengthen its expertise in book printing and finishing thanks to a strategic investment. In mid-November, the company installed a Kodak Magnus Q3600 Titan CTP, replacing two older Magnus Q3600 systems. Capable of handling plates ranging from 483 × 394 mm to 1,600 × 2,083 mm, the Magnus Q3600 Titan incorporates advanced features such as KODAK SQUARESPOT technology for faster, more reliable engraving, and the new Fusion Drive feature for improved engraving head positioning. With a multi-pallet loader (MPL), the machine can handle up to 7,500 plates in line, and reach a speed of 52.6 plates per hour (pph).

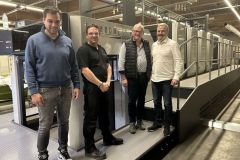

OTT Imprimeurs (67) reinforces its fleet with a new Komori GL-840P Advance

Wasselonne-based OTT Imprimeurs SAS has taken a further step in the automation of its equipment with the installation of a Komori GL-840P Advance 8-color press. Equipped with the latest technologies such as the H-UV LED system, PQA-S colorimetric control cameras, A-APC asynchronous plate setting and Parallel Control simultaneous washing, this press also incorporates Auto-Pilot for optimized in-line control. This new equipment, the third GL-40 Advance model to join the company in less than three years, is part of a strategy to combine productivity and environmental quality.

Traphot (92) adopts laser cutting with the NRGL 1612 from SEI Laser France

Montrouge-based Traphot, a specialist in high-end image processing and digital printing, has expanded its technical capabilities with the acquisition of the NRGL 1612 laser cutting machine from SEI Laser France. Featuring advanced functionalities, the NRGL 1612 stands out for its cutting finesse and its ability to work on a variety of materials.