Plockmatic completes its ColorCut Morgana series of digital creasing cutters with the SC7800 Pro-RS XL, a compact B2-format model. First presented in October at Printing United in Florida, the new machine is now available to order.

The SC7800 Pro-RS XL is based on a triple-tool architecture combining cutting, creasing and perforating. The distinctive feature is a patent-pending tangential grooving tool: this tool combines a convex and a concave part to reproduce a male/female effect comparable to that obtained on a platen press.

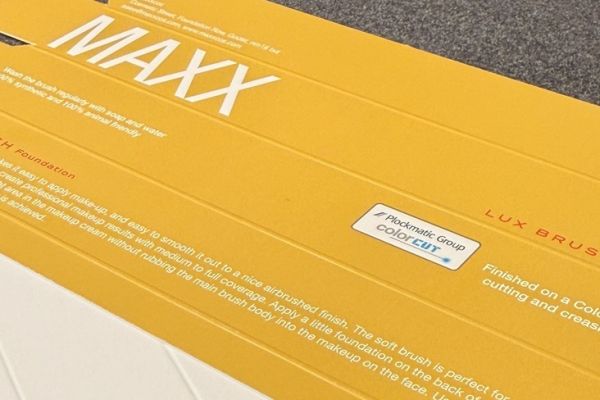

In concrete terms, the pressing and molding tools work simultaneously above and below the sheet. The Swedish manufacturer claims to obtain a "shaped" creasing rather than simply a marked surface. This configuration differs from one-sided impact die-cutting tables, where creasing is performed from one side only. This improves the production of double-sided folds.

The machine accepts sheets up to 520 x 740 mm, i.e. B2 format, with a maximum thickness of 450 microns. Synthetic substrates are also compatible. These features open the way to applications such as lightweight packaging, folders, folders, point-of-sale advertising or small box runs, Plockmatic cites.

Loading capacity up to 1‚euros000¬ sheets. Registration is based on the SmartMark system via the ColorCut Pro software supplied.

The SC7800 Pro-RS XL features a QR code-based workflow. Stacked sheets can contain several different jobs within a single stack.