Kyocera is introducing its first ever textile printer, Forearth. The Japanese manufacturer has designed this printing system to replace dye-based processes and offer a solution that requires less water.

Forearth is an all-in-one CMYK plus 4 color printing system with a printing width of 1800 mm. This digital machine offers a resolution of 600×600 dpi and reaches a printing speed of 250 m 2 /h. Forearth uses a new pigment-based ink formulation and applies the primer and finishing agent from the inkjet head.

99% less water consumption with Forearth

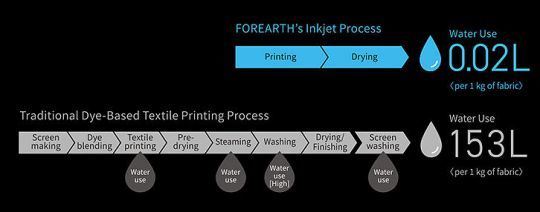

With this pigment-based, non-dye-based ink, the system eliminates the pre- and post-processing required for traditional screen printing','www.printindustry.news/search/serigraphy');" class="lien-auto-article" href="https://www.printindustry.news/search/serigraphy">screen printing and reduces water consumption compared to traditional textile printing by 99 percent, according to Kyocera tests, requiring only 0.02 liters of water compared to 153 liters for a 1 kg of printed fabric. The two-step system (printing and drying) is also much more compact.

No more hard touches with pigment ink printing

With this new inkjet machine, Kyocera would also solve the classic problems of pigment printing: the Japanese manufacturer assures that its new pigment ink printing technology offers soft-touch prints as well as high durability and compatibility on a wide range of fabrics including cotton, silk, polyester, nylon and blended fabrics.

Kyocera recommends this textile printer for many applications including women's wear, sportswear, baby wear and home textiles.

Forearth will be introduced to the public for the first time outside Japan at the ITMA 2023 International Textile and Apparel Technology Exhibition, to be held in Milan, Italy, from June 8 to 14.