In a rapidly changing textile sector, manufacturers of printing equipment and solutions are seeking to reconcile creativity, productivity and sustainability. Among them, Shaun Holdom, Fujifilm's Global Business Development Manager, keeps a close eye on the evolution of technologies and their impact on the competitiveness of workshops. His view puts into perspective the limits of sublimation and the recent contributions of UV inkjet.

"For some time now, textile printing has been seen as a growth sector in its own right. From bespoke T-shirts and hoodies to large-scale textile exhibits, there's no shortage of opportunities for industry players.

However, competition is fierce, and many printers are engaged in a merciless battle for the most profitable orders and long-term relationships with interesting customers. Which brings us to the following question: how can you make the most of a market as competitive as it is booming, without having to cut costs?

One of the most effective ways of standing out from the ever-increasing number of competitors is to deliver top-quality work on every project. To achieve this, your production equipment needs to be up to date and operating at peak efficiency. You may need to make new investments, but before you go too far, start by considering all your options.

Sublimation, the historic industrial process of textile printing

The main technology traditionally associated with textile printing is sublimation, a process that first appeared in the mid-1950s. It uses inks with aqueous dyes which, when heated to between 190 and 205°C, turn into gas and adhere to the receiving surface.

Sublimation comes in two forms. The first is transfer printing, where the image is first printed on paper before being transferred to the fabric using heat. The second is direct-to-textile printing, where the ink is applied directly to the fabric, then fixed with heat or steam.

For some, it's the ideal approach, as material and ink costs are generally lower than with other methods, making it a suitable solution for more standard jobs (soft textile signage, promotional items and garments produced in short runs). Sublimation also enables users to create vibrantly colored visuals that are lightweight, easy to fold, ship and install. All these advantages have boosted its popularity, outstripping that of heavier, more rigid display materials.

However, sublimation has its limits. The material to which the motif or visual is applied must contain polyester, nylon, acrylic or have received a ceramic treatment, as inks will only adhere to compatible surfaces. Color homogeneity and repeatability can also be difficult to achieve due to the two-stage transfer process, while thermal requirements imply probably higher energy costs.

UV inkjet, the technology on the move

UV printing is a technology that challenges the status quo of sublimation in the textile sector. Relatively new to the market, its textile applications are still limited. Without a double pass, colors lack depth and inks are often fragile, making them unsuitable for textiles that need to be folded or sewn.

Fujifilm has developed UVijet ink to solve these problems. Thanks to a unique pigment dispersion technology, UVijet ink features a higher concentration of pigments. The resulting ink film delivers vibrant colors, without the need for a double pass. These inks are also much more flexible than previous formulations, so they can be incorporated into textiles and fabrics intended for sewing or folding.

UVijet also addresses concerns about the sustainability of UV inks, as the end-of-life recyclability of prints produced using both technologies is generally comparable.

What's more, over 90% of UV ink is used in the final print, compared with only 50% for sublimation, due to evaporation during the thermal transfer process. The result: higher ink yield and efficiency, reduced waste and better overall ROI, further narrowing the environmental gap between the two technologies.

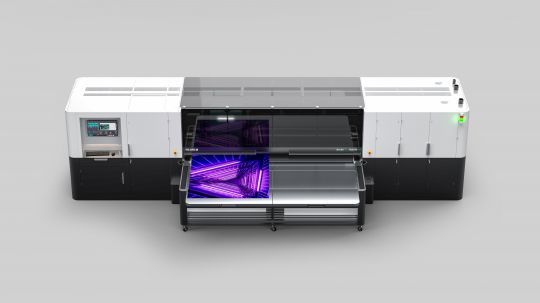

The Acuity Ultra Hybrid and these new Fujifilm UV inks

Fujifilm's Acuity Ultra Hybrid is equipped with these new UV inks. Equipped with Kyocera print heads, it enables print providers to produce bright, eye-catching, photographic-quality documents on a wide variety of substrates. This gives print providers access to profitable opportunities in a wide range of fields, including retail, exhibitions and high-end posters.

Towards coexistence or technological changeoverâeuros?

This is not to say, however, that sublimation has had its day, or that UV inks are now the only technology worthy of preference for textile production. Sublimation is still a highly effective option for creating vivid, short-run textile applications.

But advances in UV inkjet technology are enabling printers to push back the boundaries of what's possible with flexible textile applications. By combining inks such as Fujifilm's UVijet with cutting-edge hardware solutions, such as the Acuity Ultra Hybrid, there's no doubt that many new markets will open up to our customers, both promising and profitable."