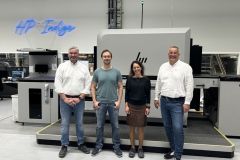

Two years after its installation in Montceau-les-Mines in Sa√'ne-et-Loire, in a building of 4‚euros000¬ m 2 with the acquisition of two new presses, the IGR Group is reinforcing its digital printing fleet. Faced with an increase in this segment, the printing company with 23 employees and sales of 3.7 million euros was looking to breathe new life into its business.

IGR will be replacing its Konica 6100 with a Konica Minolta AccurioPress C14010S and a Fujifilm Revoria 85S. Scheduled for delivery in 2025, each will be dedicated to a specific use, corresponding to the different markets covered by the printer.

Two digital presses for two uses

With white toner, the new Konica C14010S, which went into production in September, is used for long runs such as brochures, glued square backs, small packagings or religious icons on metallic paper, of which IGR produces 40,000 copies a year. "The AccurioPress runs at 140 pages per minute, with the AIT automatic inspection system that scans each sheet during printing to check register and colorimetry, and automatically ejects defective sheets says Jean-Philippe Neuville, CEO of IGR.

He explains: "It is equipped with six paper loading trays, three of which are extra-large, enabling us to produce 5‚euros000 to 6‚euros000¬ sheets in the evening in masked time."

Fujifilm's Revoria 85S toner press, installed in July, is dedicated to short runs and jobs with specific finishes: cardboard, administrative paper, covers. Slower than the Konica, it features a gloss varnish and fluorescent pink, used to extend the colorimetric spectrum. "It's not a machine we picked up for speed, but to make small runs, with varnish and thicker papers". The press is thus dedicated to short runs requiring more makeready or high added value.

This two-machine configuration meets a need for differentiated production. "We decided to take two machines and really make different products on each one." continues Jean-Philippe Neuville. "Konica produces long runs, Fuji short runs with added value."

And full file automation in sight by 2026

In addition to the machines, IGR is now structuring the automation of its production. A test phase is underway with the software editor OneVision to automate impositions. And the group is now using the API version of GameSys management software, to ensure the link between the generation of quotations and the automatic sending of files to production. It is also developing an artificial intelligence-based interface to automatically process quote requests.

"Automation is a necessity, a necessary step" sums up the Chairman. Full deployment is scheduled for the second half of 2026.

This development of tools is part of a broader strategy of consolidation. In a market under pressure, the group is now counting on stable volumes, supported by the diversity of its outlets, between web printing, digital, offset and finishing. "We're doing pretty well, we're multi-sector, both geographically and in terms of products. We work for local authorities as well as large corporations, at national as well as local level."