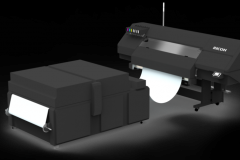

Japanese manufacturer Ricoh launches a new range of digital color presses, the Pro C5400 series, replacing the Pro C5300S series (Pro C5310S, C5300S and Pro C5300SL models). The Pro C5400 series supports a variety of media types, including coated paper, synthetic media, envelopes, transparent folders and long sheet printing up to 1,300 mm.

A first: the Pro C5400 series staples in water

One of the outstanding features of this new series is the new finishing module. Ricoh has introduced metal-free stapling using water. Unique in the industry according to the manufacturer, this function, which works by pressing the moistened sheets, can hold up to 16 sheets at an angle or 12 sheets in double stapling.

In addition, the folding module has been redesigned to make it even more compact: 209 mm wide, compared with more than double the previous width.

Time-saving start-up and digitization

What's more, the manufacturer claims a fourfold reduction in warm-up time: the Pro C5410S goes from 120 to 26 seconds, while the C5400S boasts 30 seconds.

Scanning speeds are also improving, with times cut by a factor of three to 300 images per minute in duplex mode. AI-assisted orientation detection and seamless handling of small formats, such as business cards, should also enhance scanning capabilities.

Special attention has been paid to paper transport stability, with an enhancement to the Vacuum Feed LCIT module. This ensures more consistent feeding, particularly useful for double-sided printing and extended formats.

Ricoh also announces improved image alignment accuracy and reduced set-up times.

5 times more recycled materials in Pro C5400 printers

The Pro C5400 series incorporates more recycled plastics, with a five-fold increase in recycled materials over the previous generation.

Last but not least, improving production workflows also involves software enhancement. The user interface has been designed to facilitate pre-press adjustments, limit technical interventions and optimize job sequences.