Ricoh's approach to the Fespa Global Print Expo 2025 (May 6-9 in Berlin, Germany) is geared towards textile production flexibility. The Japanese printer manufacturer will be showcasing its direct-to-film (DTF) and direct-to-garment (DTG) technologies for manufacturers, fashion designers and textile personalization workshops alike.

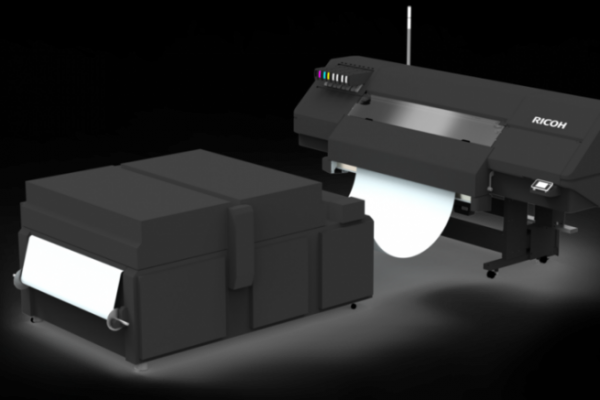

Ricoh Pro D1600 DTF for high-speed film production

The Pro D1600 DTF system will be Ricoh's headliner on the textile stand. This printer boasts an effective width of up to 1,300 mm and a print speed in excess of 20 m/min 2 /h.

Equipped with Ricoh industrial inkjet printheads, this equipment is designed for high-productivity service providers, in a context where short-run personalization is becoming a recurring requirement in fashion, merchandising and event textiles.

DTF technology enables patterns to be transferred to a wide range of textile substrates (polyesters, blends, cotton, etc.) via a special film on which they are printed.

Ricoh Ri 4000 DTG printer for direct printing with integrated pre-processing

Another solution on display was the Ri 4000. This printing system is aimed more at textile printers looking for a compact, versatile DTG machine.

Ricoh's Ri 4000 DTG printer features automated pretreatment management, which optimizes pigment ink adhesion and ensures consistent color reproduction, even on technical or dark fabrics, Ricoh assures.

This system, designed for industrial use, is accessible while maintaining professional standards of quality and productivity, with fast cycle times and low maintenance.

ColorGate 24 color management at the heart of the Ricoh ecosystem

All the textile equipment presented by Ricoh will be controlled via version 24 of ColorGate Productionserver, the RIP developed in-house. The aim is to provide complete control of the graphics chain, from file creation to inkjet workflow management, guaranteeing color fidelity even when printing directly on textiles.

This centralized control station offers functions specific to textile printing: linearization, ICC calibration on fabric and dynamic ink management according to the printed material.

Industrial outlets for its Valvejet technology

In addition to textile personalization, Ricoh will take advantage of Fespa to showcase other uses for its inkjet technology, notably through its Valvejet head. Designed for high-viscosity inks and extended throw distances, it enables direct printing on complex or bulky objects. In Berlin, tire printing for the high-end market will illustrate its ability to be integrated into industrial personalization chains.