Mimaki refines its offering for the high value-added personalization and marking markets with the UJF-7151plus II e. This new UV flatbed printer offers significant technical advances: printing on objects with irregular surfaces, pronounced textured effects, better management of rigid substrates and reduced ink consumption.

Printing on surfaces with up to 10 mm of unevenness

The major new feature of this flatbed table is LD Mode, a device that enables the printer to maintain a high level of precision on substrates with up to 10 mm height difference. This feature ensures stable printing on molded, curved or stepped objects, according to Mimaki.

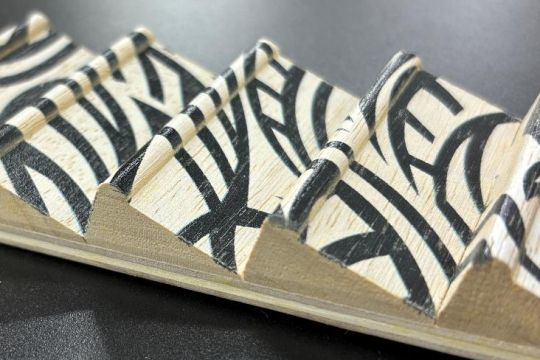

With the UJF-7151plus II e, 5 mm-thick visual and tactile effects

The second advance of this table, which supports variable data, is relief printing, which can be up to 5 mm thick. This capability makes it possible to imitate complex textures, tactile effects or produce embossed effects directly on the object.

Glass, wood, metal... a variety of supports up to 30 kg

And the third new feature is its printable primer for adhesion on substrates such as glass, metal, wood or acrylic. In a combined flow using two coats of color, plus white and primer, speed would be up to 3.7 times greater than that of previous models.

What's more, the table supports up to 30 kg of supports, a higher weight than comparable systems.

Up to 40% ink savings with Ink Saving

Finally, the UJF-7151plus II e's Ink Saving function, according to Mimaki, reduces ink consumption by up to 40%, while maintaining color quality and fidelity.

1800 DPI resolution, Greenguard Gold inks and integrated maintenance functions

Compatible with Greenguard Gold-certified UV inks, the UJF-7151plus II e also offers 1800 DPI resolution. The flatbed supports CMYK inks as well as light tones (cyan light and magenta light), for better management of subtle gradations, particularly on skin tones or landscapes.

The UJF-7151models plus II e also incorporates a number of features already present on its predecessors: the Nozzle Check Unit (NCU) to detect clogged nozzles, the Nozzle Recovery System (NRS) to automatically compensate for faulty nozzles, and the Colour Gloss function to achieve gloss or matt effects without clear varnish.