Reduced operator workload and increased productivity

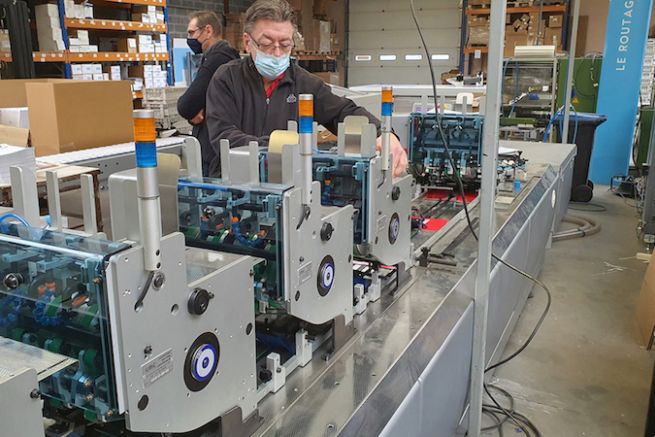

For some time now, Ethap Printing has been planning to renew the routing part of its workshop. Its choice naturally fell on a machine from the same manufacturer with the acquisition of a CMC 150 to replace a Mail 2000.

"?Elle is more flexible in terms of format, lower - which is important for our operators when loading the feeders because the back is less stressed than before - quieter, and above all more productive, which allows us to stay compétitif?" explains François Trinel, community manager of the printing plant.

Focus on support and customer service

After a year 2020 that was rather atypical for everyone, with a few uncertainties linked to the market, the printer nevertheless managed to pull through.

"?Les some recent investments have allowed us to refine our offer, it is a real advantage to have an ultra complete workshop, offset, digital, signage, ennoblement, routing...?", rejoices François Trinel.

In previous articles, Graphiline presented the different stages of the investment plan of the Entreprise Adaptée Ethap Groupe, in the wide format and the shaping .

"?Nos customers, partners, agencies with whom we work know that we are able to meet their needs in a very reactive way with an irreproachable quality of service and production.?»

Development of a website dedicated to CSR

Although the CSR approach has been growing for some time, it has been in the genes of the Ethap printing company for more than 30 years as an Adapted Company.

"?Ethap is now known and recognised as a partner of a circular, social and solidarity economy, our customers and partners no longer hesitate to communicate on their network the fact that they produce in an eco-responsible, social and solidarity-based way at Ethap Groupe.?»

The group is currently developing a website dedicated to CSR that will eventually allow customers and partners to have access to all information in this area, for example on the production of their products.