Mimaki introduces Trapis, a flexible, two-step textile transfer printing system. Available later this year, this solution with a maximum web width of 1,610 mm offers an easy-to-use solution, capable of printing on a multitude of materials, including natural fibers, and is environmentally friendly, with wastewater reduced by almost 90% compared with traditional methods, assures the Japanese brand.

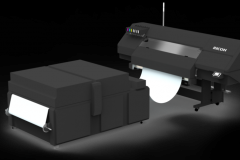

Comprising an inkjet printer and a calender, Trapis operates in a very simple way: the pattern is first printed on dedicated transfer paper by the inkjet printer, then transferred to the textile substrate via the calender.

According to Mimaki, Trapis distinguishes itself from traditional sublimation printing methods by generating minimal wastewater during automatic maintenance. "As no pre-treatment or washing of the fabric and cylinders is required, this saves around 14.5 liters per m 2 of water compared to digital sublimation printing" according to Mimaki's research.

What's more, this low water consumption eliminates the need for wastewater treatment.

Another major advantage of the new system lies in its ability to use a single type of ink on a wide range of materials, including natural fibers such as cotton and silk, as well as blended fabrics.

What's more, Mimaki claims that textiles printed with Trapis retain their extensibility while preserving their breathability and water absorption capacity.

The name "Trapis" is a combination of the words "Transfer", "Pigment" and "System".