For over 60 years, process automation has been seen as a lever for improving efficiency, reducing costs and alleviating labor challenges. Today, the printing industry is no exception to this trend, adopting advanced automation technologies to survive in an increasingly competitive market.

Optimize workflows to improve margins

Every process in a âeuros print shop, from sales to âeuros delivery, is a sequence of tasks that can be slowed down by bottlenecks. Workflow automation removes these obstacles by automating repetitive tasks and standardizing processes. The result is time savings, lower costs and better management of human and material resources.

Workflows are the documented, reproducible rules, protocols and processes that guide every stage of production, from sales pitch to final delivery. Every malfunction or bottleneck in these processes represents a risk of financial loss. Automating these flows not only reduces these risks, but also optimizes every stage of production.

For example, by automating the integration of orders into production, processing errors are reduced and deadlines are more easily met.

Steps to successful automation.

Before embarking on the acquisition of new tools, it is essential to carry out a rigorous self-assessment of current workflows. This involves listing each production process, identifying those responsible, and understanding where the friction points lie. Once this assessment has been carried out, the next step is to reduce order processing times.

The key to successful workflow automation is good planning. Here's an example of the key steps involved in obtaining a clear view of the areas to be improved and prioritizing the processes to be automated:

- Evaluate existing production flows identify workflows for each type of printed product, and note which steps have already been automated.

- Responsibility and management of bottlenecks appoint people to be responsible for each flow and for resolving any problems that arise.

- Interaction between services clarify the rules of interaction between departments, such as sales, production and customer service.

- Change request management : Set up an automated system to manage file changes or modifications during production.

- Stock management and consumables orders automated inventory management systems can also be put in place to ensure that materials are available when needed, minimizing interruptions to the production line.

The benefits of automation.

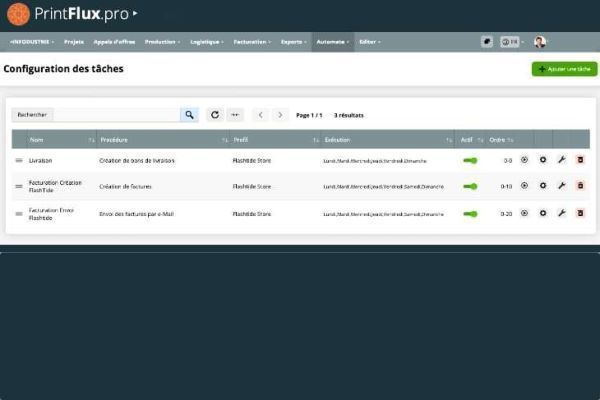

By automating repetitive and time-consuming tasks, companies can not only improve their productivity, but also offer their customers a better quality of service. Systems such as PrintFlux.com our solutions integrate an automated flow from order to delivery, reducing human error and optimizing productivity and inventory management. The result is lower costs and higher profit margins.âeuros

Human challenges in automation.

While the benefits are clear, the adoption of automation also poses challenges, particularly when it comes to managing human resources. Human error is often at the root of production slowdowns. Although the industry is trying to reintroduce apprenticeships to compensate for the lack of skilled labor, repetitive and complex tasks are better managed by automated systems. Automation frees teams to concentrate on higher value-added activities, while guaranteeing more consistent and reliable results.

The road to end-to-end automation

The future of the printing industry lies in fully automated workflows. It is essential to connect the various "islands of automation" present in a printing plant to achieve an integrated workflow. This requires complete software solutions, from order to delivery. A well-honed process may take several months to set up, but each automated step brings a gain in efficiency that contributes directly to improved margins and customer satisfaction.

Automation is a key element in ensuring the competitiveness of the printing industry. However, it requires careful planning and strategic management of human resources to be fully effective. By gradually integrating these technologies, print businesses can not only improve efficiency, but also prepare for future market challenges.