Laminating becomes an in-line operation on Konica Minolta AccurioPress digital presses. The Japanese manufacturer has just unveiled the GBC CL-401, an inline laminator capable of processing prints at the press output, in a single pass, without interrupting the production flow, according to Konica.

The module was designed by GBC, a brand of the American ACCO Brands group. According to Jim Sawyer, North American Sales Director for Acco Brands/GBC, it is "the first truly integrated on-demand laminating solution online" .

Cold lamination, with no heat-up time

The system is based on a cold lamination process, enabling immediate application without a preheating phase. It can be laminated on both sides, or on one side only, making it ideal for the production of self-adhesive media and decorations.

The unit handles media from 75 to 300 g/m 2 and A4, A3, SRA4 and SRA3 formats. Automatic detection of film type and width, together with the LCD control screen, facilitate operator adjustments. The module is compatible with a wide range of plastic films. Konica Minolta reports that the unit can operate at 100% press productivity.

Complete integration into the production workflow

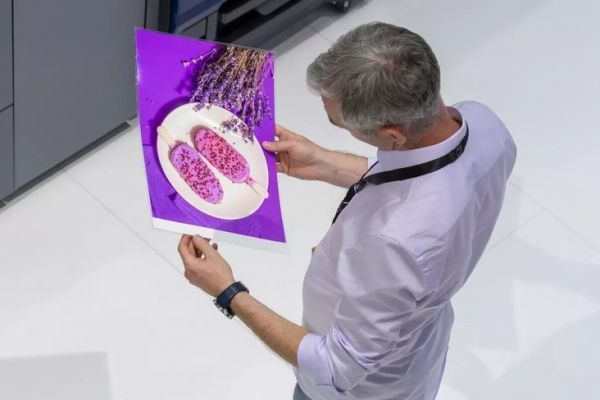

The CL-401 laminating module can be combined with Konica Minolta's TU-510 die-cutting unit to enable fully in-line production, including full-page printing and trimming. This type of configuration is particularly suited to applications such as menus, flyers, covers or posters, which require rigidity, durability and tear resistance.

Ines Wennemann, senior product manager Professional Printing at Konica Minolta Business Solutions Europe, points out that this new product complements the brand's existing range of inline finishing modules.

For Jim Sawyer, this solution makes it possible to "transform a frequent bottleneck into a smooth production flow" .