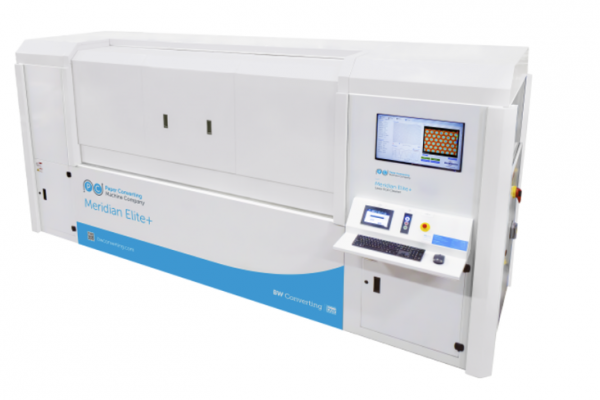

In flexography, anilox roller maintenance remains a strategic lever for maintaining print quality and optimizing production line productivity. To optimize the productivity of these workshops, BW Converting has launched the Meridian Elite+, the latest evolution of its laser roller cleaning technology. Officially unveiled at the InfoFlex 2025 Forum to be held in Pennsylvania in early May, this new equipment combines in-line inspection, adaptive intelligence and connectivity.

Print quality through inline inspection

Stable cell volumes on anilox rollers are essential to guarantee consistent print quality. The integration on the Meridian Elite+ of an automatic cell volume measuring microscope, operating before and after cleaning, enables instant verification without human intervention. The system also continuously adapts the power of the laser beam according to the degree of contamination detected, to preserve roller life.

This innovation is primarily intended for workshops wishing to reduce color deviations and defects associated with partially clogged rollers.

Intelligent laser cleaning

The new system is also equipped with Adaptive Laser technology, which adjusts cleaning intensity in real time according to the condition of the detected roller. This dynamic approach has been designed to reduce the risk of over-cleaning, which could damage anilox ceramics, especially those engraved with laser or fine screen.

The Meridian Elite+ connected to reduce maintenance and manage operations

The Meridian Elite+ is equipped with a cloud-hosted database that stores the cleaning history of each roll. This computerized tracking should enable flexo shops to better plan preventive maintenance, thus limiting the risk of premature anilox deterioration.

What's more, the cleaning system meets Industry 4.0 standards with its functionalities enabling remote monitoring, trend analysis and predictive maintenance.

Towards longer-lasting, more economical cleaning

BW Converting eliminates the use of water, chemical solvents and compressed air with this equipment, thus considerably reducing operating costs and environmental impact, stresses the American manufacturer. This process should be of interest to companies committed to environmental certification.