From taking orders through different channels to creating quotes, amalgams and varnish masks to creating delivery notes, prepress workflow automation software can handle a wide range of tasks. But what does this mean in practice for the Euro business owner?

OneVision, which has been developing automation software solutions for commercial printing, large format, packaging and publishing for 25 years, gives us the top seven reasons why printers should move to file preparation and workflow automation.

1 Avoid bottlenecks

As printing and finishing machines become faster and faster, the bottleneck in a printing company's production is nowadays at the prepress level.

And with the increase in the number of jobs and the decrease in the quality of incoming files, the prepress staff is constantly under pressure.

Automating the creation of quotations, production files, preparation of print files, preflighting, creation of varnish masks and cutting files significantly reduces prepress time.

2 Reduce waste

The automation of the prepress and the production workflow allows the optimization of each print. For example, the OneVision software solution allows for the automatic creation of amalgams. In addition, print files are created and checked automatically, which reduces errors and therefore reprints.

3 Keeping prices low

End customers expect low prices for printed products and fast delivery times. If jobs have to be handled manually one by one, the margin is reduced.

4 Shorten delivery times

The principle of automation is that it reduces production time. With shorter production times, delivery times are shortened. With customers increasingly in a hurry, this reactivity is highly appreciated.

Benjamin Rüdt von Collenberg, head of the German printing company InForm Etiketten, testifies: "With a label containing many finishes, manually applying all the finishes is laborious, and more importantly often fails. With OneVision's workflow solution, this is much faster and more reliable. (Euros) A label that used to take two hours can be processed in 15 minutes thanks to automated processes that are either actively executed by the graphic designer in prepress or run automatically in the background."

5 Increasing volumes

And shorter production and turnaround times allow printers to complete more jobs. It is also possible to increase volumes with web-to-print solutions.

6 Optimize customer service

With recurring tasks automated, staff can focus on customers and increase their satisfaction and loyalty.

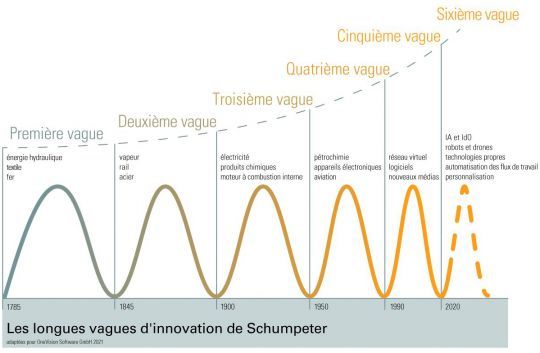

7 Don't miss the innovation train

Innovation and technical progress are the main drivers of economic progress. According to Schumpeter's theory of innovation, industries that do not keep up with the technological movement are doomed to disappear and to be replaced by new development opportunities.

The automation of non-value-added tasks is one of the major advances of recent years

The OneVision team will be present at the Cprint exhibition in Lyon from February 1st to 3rd, 2022, stand 2N22, to answer all your questions.