Since its creation in 1996, Loire Impression has been on a steady growth trajectory. In 2022, the company achieved sales of 1.7 million euros, before crossing the 2 million euro mark in 2023. This momentum continued in 2024, with sales expected to reach between 2.3 and 2.4 million euros.

These results testify to steady growth, which management intends to accelerate over the coming years. CEO Alexandre Leroy forecasts sales of 4 million euros by 2028, with the aim of doubling this figure by 2030. This ambition is underpinned by a solid growth plan, structured around three axes: modernization, automation and eco-design.

These forecasts are based on the company's recent investments, namely the 4 million euros injected into the construction of new premises and the renewal of production equipment.

The new premises, located in Distré, give the company a surface area three times larger than before, offering new prospects for development, particularly in visitor reception and eco-design training.

With clearly defined objectives in terms of environmental responsibility, Loire Impression has placed eco-design at the heart of its development. The Saumur-based printing firm has reoriented its purchasing practices, focusing on environmentally-friendly materials.

Alexandre Leroy, the company's Managing Director, emphasizes: "We have reoriented our purchasing policies for paper and inks, and are putting pressure on our suppliers .

The company now turns to local suppliers whenever possible, to limit the carbon footprint associated with sourcing.

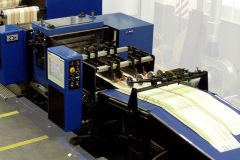

Service diversification and large-format printing

Diversification is one of the three pillars of Loire Impression's growth plan. The arrival of new machines enables the company to adapt to a wider range of demands, notably thanks to equipment dedicated to very large-format printing.

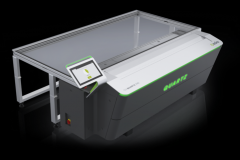

Komori Lithrone G29

One of the major advantages of the Lithrone G29 is its extremely short makeready time, which significantly reduces production lead times. This feature is particularly beneficial for companies handling a varied volume of orders, with short to medium run lengths.

Equipped with the Komorimatic dampening system, the press guarantees consistent, precise print quality, even for mass production runs. This device effectively regulates the amount of water applied to the plate, which is crucial to avoid variations in quality between copies.

The press-integrated H-UV UV curing system is one of the highlights of the Komori Lithrone G29. This innovative system uses a single UV lamp and high-sensitivity inks, enabling immediate drying right off the press. In addition to speeding up production times, this system helps reduce energy consumption, while guaranteeing better print hold on a variety of substrates.