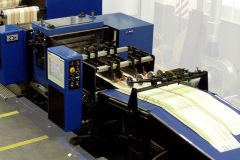

The Lithrone GX/G advance series expands. Komori has added the Lithrone GX29 advance to its range of perfecting offset presses, developed to offer an excellent return on investment. This latest addition features a unique 61 x 75 format, suitable for a wide range of production applications from commercial to light packaging.

29", the mid-size format designed for performance

This intermediate format of 61 × 75 cm (24 x 29.5 inches) streamlines imposition on jobs such as cards, films, cigarette cartons or compact pharmaceutical packaging, says Komori.

This atypical print size offers a compromise between compactness and material profitability, particularly for jobs where traditional 70 x 100 or 52 x 74 formats are not always the most efficient.

This duplex press operates at high speed, even on thick substrates. This capability is based on improvements to the feeder, sheet delivery and amalgamation system. Three technical areas in particular have been reworked: the Komorimatic humidification system, ink control and the KID operator interface, which has been redesigned to facilitate access to functions.

The GX29 advance for special substrates

The GX29 advance can print on a wide range of uncoated, plasticized or synthetic substrates: PET film, polypropylene, metallized paper, opaque paper, and so on. This feature will appeal to printers of flexible or promotional packaging, as well as to the high-end label and publishing markets.

Komori also highlights the press's integration into automated production environments thanks to its KP-Connect Pro management system, enabling real-time communication between prepress, printing and finishing stages.

Three functions for a better ROI

The manufacturer's "advance" series is presented as the series with the best return on investment (ROI), and is equipped with several features designed to improve the machine's overall energy efficiency while reducing paper waste.

The first, called Smart Inking Flow, is based on an inking roller architecture that lowers the operating temperature.

The second, a DC blower developed in-house, promises constant air flow at low power consumption.

Last but not least, the e-Mist function adjusts the humidity level on the sheets to stabilize transport and limit static discharge.

Komori emphasizes the balance between industrial performance and a reduced carbon footprint, in line with new customer expectations.

Other technical specifications have not yet been released.