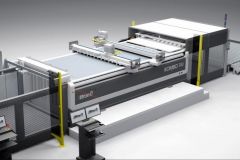

Müller Martini unveils its new high-production book finishing machine. The SigmaLine version 3, which should have been presented at Drupa 2020, is the fastest digital finishing machine on the market: it shapes up to 305 m/min.

First introduced in 2004, this finishing line combines digital printing and finishing in a single system, allowing for one-pass automated production from PDF file to book block, and when combined with a bindery line, to the finished book.

About fifty examples of this Swiss manufacturer's book production line have been installed around the world. In France, two of them are at La Nouvelle Imprimerie Laballery located in Clamecy (Nièvre) and managed by Hubert Pédurant, a SigmaLine 1 and a SigmaLine 2.

The third generation has two major new features, as Philippe Michelon, Müller Martini's Sales Director for France, explains.

Dynamic cutting on the SigmaLine 3 to reduce blank pages

The SigmaLine 3 is equipped with a dynamic cutting mode and a folding machine, no longer mechanical with knives, but pneumatic.

"These two elements allow for the pagination of the last signature to be changed. This reduces the number of blank pages. Previously, it was possible for a 32-page signature, for example, to have 31 blank pages. With this dynamic cut and the new folder, the signature could have a maximum of seven blank pages."

Possible pre-assembly for sending to a sewing machine

The other major innovation is the pre-assembly system of the Sigmaline 3.

"Multiple signatures can be pre-assembled before being folded together. This allows several separate signatures to be combined into one. For example, three 8-page signatures can be made into one 24-page signature. This is useful for preparing signatures that need to go through a stitcher or saddle stitcher."

A finishing line ideally coupled with an inkjet press

Like the other SigmaLine, this finishing line is the master of the entire production line. "The printer's press will be integrated into this machine. It is the Connex LineControl that drives the press, whether it is a KBA, Kodak, HPâeuros¦ and the finishing line. And if a print is not correct, it is immediately rejected and restarted from the press."

Who is this SigmaLine 3 for? "This machine will ideally be used in conjunction with a 20- to 60-inch, 8- to 40-page inkjet press, and is used primarily for the book market. I recommend it for large print runs, from 5,000 to 10,000 copies in the book world, in 30 or 40 inches." And Philippe Michelon underlines that the SigmaLine still requires 2000 to 3000 m² of floor space.