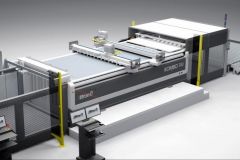

Announced last year, the SigmaLine Compact arrives on the market. Dedicated to the production of book sections, brochures and magazines printed digitally and on reels, this new finishing machine can produce more copies, with less space, fewer staff and reduced waste.

SigmaLine Compact requires only 40 m 2 and only a few meters of striker plates are generated during a format change, according to the Swiss manufacturer.

The machine handles paper reels up to 22.5 inches (572 mm). Thanks to its pneumatic folding technology, this converting line boasts very fast job changeover times: changing folding patterns from 3 to 4 folds, for example, takes less than 10 seconds, he adds.

Muller martini offers numerous configurations for this machine, which covers all binding options: softcover, hardcover, thread-stitched, stapled and saddle-stitched.

This equipment is compatible with Muller Martini's Connex workflow system, which will manage production from prepress to finished product in a fully automated way, without manual intervention.

SigmaLine Compact completes the SigmaLine lll range, dedicated to widths up to 42 inches (1067 mm) and requiring 2,000 or even 3,000 m 2 space.