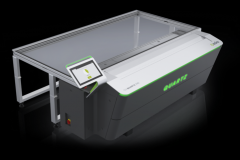

At Drupa 2024, Czech manufacturer Soma unveiled its new flagship machine, the Optima 2 10C, a high-end flexo press for very wide web packaging. The Optima 2 has been developed for extended repeat widths (370, 400, 440, 480 and 1300 mm) for the production of feed packaging, agricultural bags, cement sacks or pre-printed cartons.

With web widths of 1050, 1270, 1450 and 1650 mm, the Optima 2 10-color can reach speeds of up to 600 m/min and handles reels with diameters ranging from 1000 to 1500 mm in a variety of materials (LDPE, HDPE, PP, CPP, BOPP, PET, OPA, paper, laminate, etc.).

Soma has paid particular attention to the machine's ergonomics. The control panels are located on a movable wall close to the print control area, the operator has easy access to the drying heads, fans and cabinets thanks to safety stairs, and sliding doors allow the operator to access the anilox and print sleeves of any inactive print tray, while other trays are running.

Designed for short runs, the Optima range (Optima and Optima 2) is equipped with several automation functions that minimize time and material loss during changeovers, as well as a vibration control system (Advanced Bounce Control technology), recalls Soma. The press's modular design can be adapted to the printer's specific needs throughout its lifetime, for example by adding or removing laminating, slitting or perforating units.

At the show, visitors can watch two demonstrations of the Optima 2 10C each day.