D4 technology: a major step forward in productivity

The D4 technology integrated into the P5 350 HSR and P5 350 HS printers represents a significant advance in productivity. Capable of printing up to 670 m² per hour, these machines set new standards in terms of speed, while offering precision and reliability that reduce the need for monitoring, thus optimizing production processes.

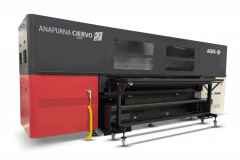

Maximum flexibility with hybrid solutions

The P5 350 HS stands out for its hybrid capability, enabling printing on both roll media and rigid cards. This versatile printer, with a maximum width of 3.51 meters, adapts to a variety of projects, offering printers a single solution to meet diverse needs. The addition of new inks, including fluorescent inks, enriches the creative options available to users.

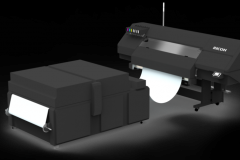

iSUB: an innovation for textile printing

In the textile sector, the P5 TEX iSUB features inline sublimation technology. This one-step printing process, reaching speeds of up to 422 m² per hour, simplifies production while guaranteeing superior print quality. This solution is particularly well suited to textile applications, offering increased efficiency and impeccable results.

Automation and sustainability: the future of printing

Durst optimizes not only the productivity but also the sustainability of its solutions. Durst automation software, combined with P5 printers, improves overall efficiency, reduces errors and enables efficient resource management. These innovations are designed to meet growing sustainability requirements, by minimizing the environmental impact of printing processes.