From the outset, Digi-Paq chose to go digital, convinced of the relevance of this technology for label printing. At a time when traditional production still dominated, the company anticipated changing customer expectations: shorter lead times, greater personalization, flexible print runs.

Co-director Christophe Parrein emphasizes: "We thought digital was going to take off, and I think we were right."

This early transition to digital technology has enabled the company to distinguish itself in a demanding market and gain in flexibility.

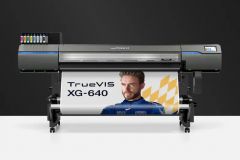

Digi-Paq has gradually replaced its older machines with newer models, all from the SCREEN range. The adoption of Truepress LABEL 350SAI-S presses offers specific advantages for label printing, including consistent print quality, compatibility with a wide range of substrates and high production speed.

One of the strengths of the Truepress LABEL 350SAI-S press is its ability to combine speed and print quality. With speeds of up to 60 meters per minute, it offers one of the highest performances of any digital printing system dedicated to labels. The Truepress Jet L350UV+ also stands out for its ability to handle thin substrates. These heat-sensitive materials can become distorted during conventional printing. Thanks to an innovative cooled roller, this press is able to maintain the stability and quality of the substrate, expanding the production possibilities for labels destined for a variety of applications. What's more, the range of inks available, now including blue and orange, enables faithful reproduction of spot colors, essential for complying with brand graphic charters. Blue ink, particularly popular for cosmetics and skincare packaging, provides more vivid hues, while orange enhances the visual impact of red areas, such as those used for food products.

One of the major challenges facing the label industry is the diversity of orders: customers expect customized prints, in small and medium runs, while maintaining short delivery times. Digital inkjet presses enable Digi-Paq to meet these requirements without compromising on quality. What's more, they offer the possibility of testing designs rapidly, making it easier to adapt to trends and new customer demands.