The printing industry is evolving rapidly, with ever higher expectations in terms of speed, personalization and cost management. Komori, through the transformation of its KGC center into an intelligent factory, proposes an automated production model, where technology and collaboration redefine the future of printing plants.

The key to this concept lies in the total automation of printing processes. Thanks to KP-Connect Pro, a production management system, all operations - from prepress to logistics - are coordinated and monitored in real time. A centralized control room enables managers to monitor each stage via screens, facilitating rapid decision-making and workflow optimization.

This level of automation enables higher productivity while reducing downtime and minimizing human error. Increased efficiency also translates into better cost management, a major challenge for printing plants faced with rising material and energy prices.

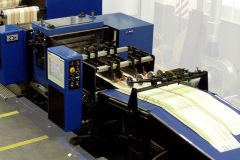

The KP-Connect Alliance Program, initiated in 2016, plays a crucial role in realizing this smart factory. This program brings together the key players in the various stages of the production chain (prepress, printing, postpress) to create an ecosystem of interconnected solutions. The integration of technologies such as autonomous mobile robots, used to transport printing plates, or CTP sorting systems, bears witness to this collaboration.

The smart factory concept also takes into account new market requirements: shorter print runs, shorter production times, and the need to reduce the ecological footprint of industrial activities. By automating and centralizing processes, printing plants can adjust their production more flexibly, while maintaining constant levels of quality.

The plant's ability to adapt quickly to changes in demand also means greater profitability, even with reduced production volumes - an essential advantage at a time when customers are increasingly looking for customization and responsiveness.

While automation plays a central role, people remain at the heart of the intelligent factory. Komori, through its KGC Printing College, has expanded its training program to include modules on smart factory operations. These training courses, whether practical or via e-learning sessions, enable professionals to adapt to new technological tools and master automated systems.