RISO's commitment to the environment is neither a strategic shift nor a belated adaptation to current standards. It has been an integral part of the Japanese group's DNA since it was founded in 1946. RISO designs systems that are sustainable, economical and limit their environmental impact at every stage of their life cycle.

RISO's unique printing technology: cold inkjet

This structural approach translates into a range of eco-designed equipment, using a printing technology unique on the market: cold inkjet. Integrated into RISO's ComColor and Valezus ranges, FORCEJET? technology is based on the principle of flat paper passage to limit jams, at high speed, with energy consumption reduced to the strict minimum.

Unlike laser or thermal inkjet processes, RISO machines have neither ovens nor drying modules. Laser toner systems require preheating to fix the powder via thermal fusion, while water-based inkjet printers require heat drying after thermal ejection of the ink.

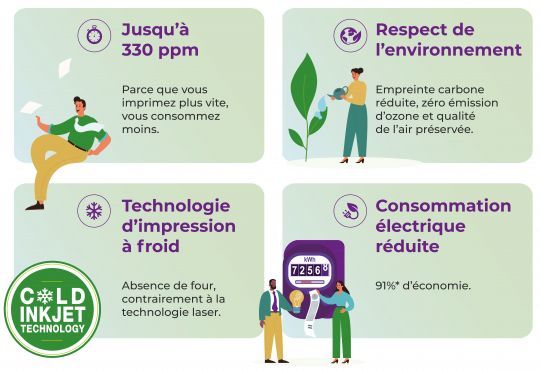

RISO's FORCEJET? technology works cold. The oil-based ink instantly penetrates the paper fibers and dries without the use of an oven or energy-intensive drying module. In stand-by mode, RISO machines don't need to keep their components hot, so they consume virtually no energy. This system reduces electricity consumption by 91%*.

Printers with a slimmer design for greater durability and productivity

This cold process also simplifies equipment architecture. RISO printers have fewer parts than traditional printing equipment, which limits the need for maintenance. The brand's inkjet models have an availability rate of 99%, with speeds of up to 165 pages per minute on the ComColor range, and 330 pages per minute on the Valezus T2200 model.

No ozone emissions into the air

RISO's cold printing technology also reduces the health impact of equipment. Unlike laser technology, RISO solutions emit neither ozone nor toner particles. Concentrations of volatile organic compounds (VOCs) are greatly reduced. âeuros¨The working environment is thus preserved, without nuisance for users, even in closed or poorly ventilated spaces.

Recyclable materials integrated into the manufacturing process

At RISO, the environmental approach begins at the design stage. Our R&D teams use recycled and recyclable materials in the manufacture of our machines. Every stage - from production to end-of-life - is designed to limit resource consumption. As a result, the recovery rate for RISO equipment is 99.74%.

Consumables recycling: a structured system with Conibi

RISO is also a co-shareholder in Conibi, an industry consortium founded by some fifteen manufacturers to organize the collection and processing of used printing consumables. The manufacturer offers its customers a simple, free solution for recovering used cartridges.

The program is based on an on-demand collection service, triggered when the volume of consumables reaches a minimum threshold, in order to optimize logistics flows and limit CO2 emissions. All waste collected is then channeled into recovery channels guaranteeing its reuse. In 2024, 11,827 RISO cartridges were recycled in France.

RISO recently deployed this service in Belgium, becoming the first manufacturer to offer the Conibi program in this territory. A logical extension of its environmental strategy, which combines rigorous management of consumables with a concrete commitment to the circular economy.

*Based on a comparison of the average of RISO ComColor FT and GL models with the average of 12 laser copiers from 40 to 60 ppm, print and standby, on the basis of 300,000 pages per year.