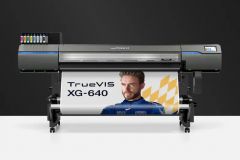

Agfa is launching a second printer in its Avinci line of dye-sublimation machines for flexible textile signage, the Avinci CX3200. The Avinci CX3200 reaches a production speed of 270 m 2 /h (compared to 123 m 2 /h for the Avinci DX3200 model).

The 3.2-meter-wide dye-sublimation roll-to-roll printer prints directly on a wide range of polyester-based fabrics or transfer paper. It uses water-based dye sublimation inks and is equipped with Kyocera water-based print heads that will cover the entire life cycle of the machine. An off-line calendering unit will fix the colors permanently.

"The market demand for flexible dye-sublimation signage continues to grow because it is lightweight, resistant to folding and creasing, and easy to transport and reuse, says Philip Van der Auwera, Agfa's Large Format Marketing Manager. The Avinci CX3200 will meet the needs of existing textile printing companies and it will allow sign and poster printers to move into textile printing and then attract new customers."

Avinci CX3200 compatible with multiple textile applications

Printing directly on the fabric is suitable "perfectly for fast processing of flexible dye-sublimation signage applications such as banners, wall graphics and point-of-purchase or trade show displays, as well as special applications requiring direct printing, such as flags."

As for the transfer paper, it allows to obtain "very crisp prints, eliminate any lag and minimize media waste." It extends the scope of application to sports and fashion apparel and interior decoration prints on uncoated polyester fabrics.

Robustness and ease of use with Agfa's Avinci CX3200 printer

This dye sublimation printer is suitable for high productivity and 24-hour operation. "It is extremely robust, reliable and easy to use." adds the marketing manager. For example, Agfa, in addition to equipping the machine with durable print heads, has simplified the changeover from one job to another: with automatic media transport, loading a new roll takes only seven minutes and only one operator.

The Avinci CX3200 is driven by Agfa's Asanti workflow software, which ensures high print quality, color consistency and low ink consumption.

Asanti also offers many features that make production easier, such as automated positioning of cut marks and grommets, as well as easy design of fabric extensions for creating flagpole pockets.

On June 22, the manufacturer is offering a virtual presentation event dedicated to this new Avinci CX3200 called "It's time to raise the curtain", at the 5d10 online studio.