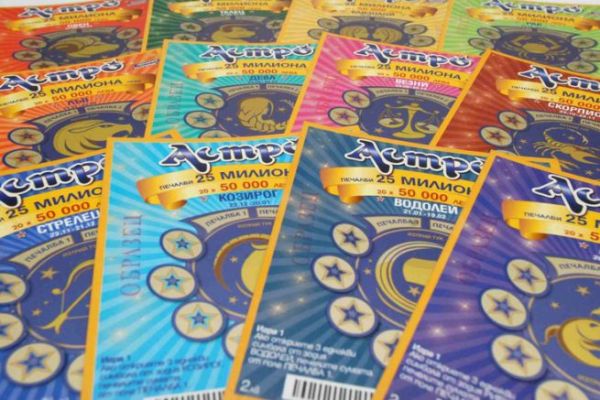

Demax is Bulgaria's largest producer of scratch cards. From its production site in Sofia, Demax manages the entire lottery ticket production process, from electronic data processing to packaging of the finished products.

Realizing that its digital ink for variable data printing was not drying at the required production speed and was hampering overall production capacity, the company was looking for a more efficient solution.

Domino's AQ97BK, a fast-drying alternative to UV inks

"In sectors requiring high-speed digital printing, UV-cured inks may be preferred for their fast-dryingâeuros properties; but this is not an option for printing on immediate-win lottery tickets, as UV inks can leave a slightly raised mark, which could reveal a prize under the scratch mark." explains James Orford, Product Manager for Domino's Digital Printing Solutions division.

He adds: "Our latest solvent and water-based hybrid ink, AQ97BK, was created to offer companies an alternative to UV printing. And it has proven to be the ideal solution for Demax's printing needs."

Scratch card production cut from three weeks to two days

Domino's AQ97BK is a new fast-drying water-based ink, specially formulated to improve adhesion over standard water-based inks, with the ability to print on coated papers, glossy substrates and Tyvek, often without the need for high-energy dryers.

By combining Domino's K600i high-resolution monochrome digital press with this new ink, scratch card production time was cut from three weeks to just two days.

Demax now produces over 100 million lottery tickets a year on five K600i printers at speeds of up to 60 m/min, and plans to roll out the solution to other parts of its production line in the near future.