With its new machine, Kurz intends to make foil stamping on paper and cardboard accessible to everyone. The DM-Smartliner unit of the German manufacturer uses the transfer metallization process. Gilles Bonnet, responsible for digital solutions, machines, foils and software at Kurz, presents this new equipment and technology.

GraphiLine: What is the Kurzâeuros DM-Smartliner?

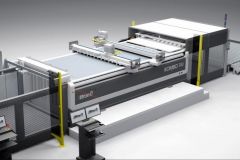

Gilles Bonnet: DM-Smartliner (DM for Digital Metal) is a digital offline transfer metalizing machine. This self-contained finishing unit gives printers the ability to apply metallization with ease, without the need for special knowledge. The DM-Smartliner is designed for burr-free and spotless deposit, high fineness and a speed of up to 3â 100 sheets SRA3/hour.

Is transfer metallization a unique Kurzâeuros technology?

This process is already used on small laminating machines, in a somewhat homemade way. Kurz has succeeded in perfecting this technology considerably with the application unit, but also with the foil that we produce ourselves.

How is this technology used in practice?

First of all, the printer prints the motif to be metallized in monochrome in digital (not inkjet) on the paper or cardboard sheet.

Then he places the sheets in the DM-Smartliner. Once heated, the machine will apply the metallization to all previously printed areas. No digital file is required, just press the start button and the sheets come out metalized.

These sheets can then be printed in offset or digital, even on surfaces with a metallic film.

Approximately 80% of our customers' jobs are done with this overprint, but there is no need to apply a new color, as we offer about 10 film colors.

What are the advantages over hot foil stamping?

With this machine, we offer the best compromise. Certainly the hot stamping is a result with a very beautiful quality, the plate will slightly emboss the material creating relief. It is a technology that works wonderfully well.

But the market is moving very fast: do customers want this very high quality or is better responsiveness more important todayâeuros?

Without the need for clichés, this machine brings a great reactivity.

In addition, difficult designs are now possible. The DM-Smartliner makes it possible to create much more delicate patterns such as borders, small texts, halftones and to blend solid colors with great finesse.

Transfer metallization is just as bright as standard hot foil stamping, or even brighter depending on the paper. This is particularly noticeable on fine lines where the fineness is enhanced by this shine.

Moreover, with our technology, the structured papers keep all their reliefs.

Another advantage of the DM Smartliner is that it can be used for very short production runs, such as pre-production runs to validate sets, for example.

What applications can be achieved withâeurosand finishing equipmentâeuros?

Boxes, cases, but also commercial prints, tickets for different fields (associations, events)âeuros¦ the applications are numerous.

And with variable data management, the DM Smartliner can be used for serial number incrementing. It can also be used for security printing with security films and random ink overprinting.

Who is the DM-Smartlinerâeuros for?

The DM-Smartliner is aimed at all printers and converters who use metallization technology, but it is also aimed at small and medium-sized companies who want to have easy access to this finish while opening up to other high-value markets, such as personalization and security printing.

And the DM-Smartliner is suitable for companies with limited space. The unit is compact (2.80 m long and 1.20 m wide), and will store very easily.

With the advantage of being able to do small to large production runs, the DM-Smartliner offers all printers the possibility of depositing high quality metallization with ease, without the need for special knowledge.