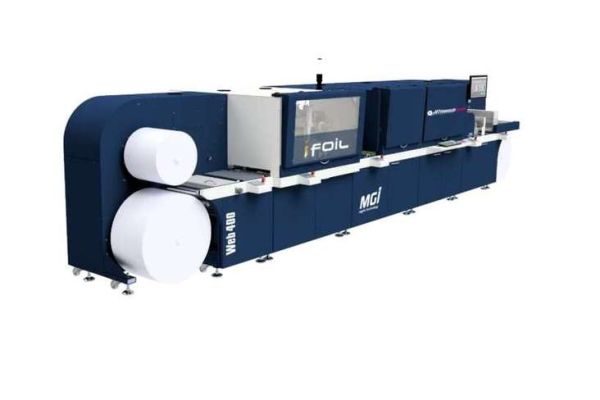

Presented at Printing United in Las Vegas and Labelexpo in Chicago in September 2024, the JETvarnish 3D Web 400 is part of the evolution of digital finishing technologies, offering an all-in-one solution. Designed for printers and converters, it adapts to the needs of short, medium or long runs, and delivers high added value thanks to its versatility and ease of use. Read more : Konica Minolta unveils its latest innovations at North American trade fairs.

The press can apply UV selective varnish and hot foil stamping to a wide range of substrates. It is suitable for offset, flexo, toner or inkjet printing, and accepts open, closed and synthetic substrates. Thanks to a 100% digital process, it produces flat or embossed finishes with varnish thicknesses ranging from 7 to 224 microns. It uses artificial intelligence via the AIS scanner for automatic registration, ensuring optimum stability throughout production, despite any material deformation.

With a production speed of up to 50 meters per minute, the JETvarnish 3D Web 400 meets the need for speed and flexibility. Its ability to produce several successive runs with on-the-fly makeready simplifies the management of multi-version jobs and on-demand personalization. This solution also makes it easier to reduce time-to-market, a major challenge for brands. The automatic cleaning system, requiring just ten minutes a day, limits interruptions and optimizes production cycles.

The JETvarnish 3D Web 400 is available in several configurations to suit printers' needs: one or two inkjet engines, with or without a hot foil module. It can also be equipped with a flexo unit or a semi-rotary die-cutter, available as options after launch. This modular approach enables companies to upgrade the machine as their needs grow, guaranteeing a future-proof investment.

The press features a simplified, tablet-based user interface, making digital finishing accessible to any operator. It is complemented by the MGI Connect software suite, which offers advanced functionalities: predictive maintenance with MGI Dashboard, cost calculation and validation of press orders in augmented reality via MGI Approve. Hosted in a secure cloud, this connected suite facilitates collaboration between printers and principals, enhancing transparency and process efficiency.