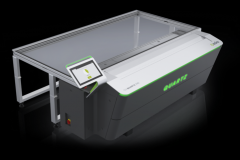

With the PlateRite 4600N series, Screen highlights the performance and adaptability of its new thermal CtPs. Available in three models, this series responds to printers' growing need for systems that offer both speed and flexibility, while reducing manual intervention. This article analyzes the technical features of each model and their potential impact on production.

Each model in the PlateRite 4600N series has been designed to meet different production volume levels. The entry-level model, the PlateRite 4600N-E, features 16-channel imaging heads and achieves a throughput of 11 plates per hour. The mid-range S model doubles the number of channels to 32, enabling production of 21 plates per hour. Finally, the Z model features 64-channel heads, with an output of 33 plates per hour, positioning this CtP at the top of the range in terms of production speed. These specifications offer printers the possibility of adapting their choice of CtP according to their needs, enabling optimized management of their productivity.

One of the strengths of the PlateRite 4600N series lies in its ability to handle larger plates, up to 830 x 680 mm, increasing compatibility with a wide range of presses. This flexibility enables printers to easily integrate these systems into a variety of production lines without limiting their ability to adapt to specific customer requirements. What's more, the CtPs in this series are compatible with different plate types, making it easy to adjust to operational needs without the need for major equipment modifications.

With this series, Screen offers advanced automation via the SA-L4600N autoloader, capable of loading up to 100 plates in a single sequence. This equipment facilitates workflows by reducing the frequency of manual interventions, thus minimizing interruptions and improving productivity ratios. However, a manual loading option remains available, enabling other plate types to be easily integrated within the same production cycle. This flexibility is a major advantage for printers whose operations require frequent plate changes.

The PlateRite 4600N series features an energy-saving mode, which significantly reduces power consumption during standby or idle periods. In addition, Screen has integrated the TRUST Network system, an online management platform that offers performance monitoring and remote maintenance for the entire series. This monitoring service enables printers to maintain reliable operation while limiting unscheduled downtime.